2026 Best Laser Cutting Machine Reviews and Buying Guide?

The laser cutting machine industry is experiencing significant growth. According to a recent market analysis, the global market is projected to reach $7 billion by 2026. This surge reflects businesses’ increasing reliance on precise cutting technology for various applications, from manufacturing to art.

Investors and manufacturers must understand the available options. Different laser cutting machines vary in power, speed, and material compatibility. Finding the right machine could enhance efficiency and productivity. Yet, many buyers overlook key specifications, leading to regrets post-purchase.

User reviews highlight that about 30% of buyers face difficulties in operation. An informed choice is crucial. Whether cutting metal or wood, the right laser cutting machine can make a significant difference. However, one must carefully consider features and costs before investing.

2026 Laser Cutting Machines: An Overview of Industry Trends

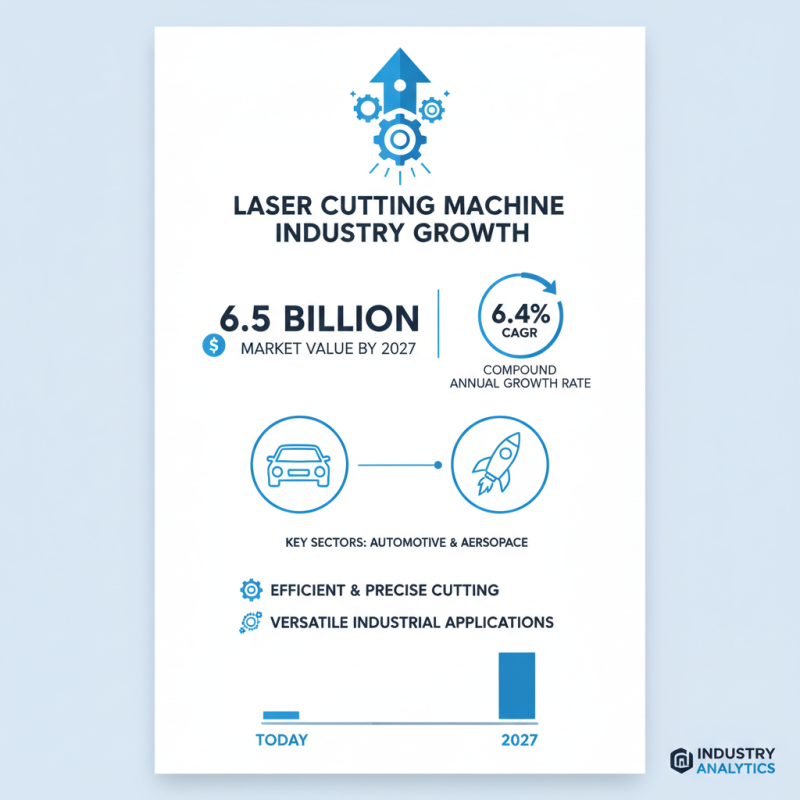

The laser cutting machine industry is experiencing significant growth. According to recent reports, the global laser cutting market is expected to reach $6.5 billion by 2027, growing at a CAGR of 6.4%. This rise reflects increased demand in sectors like automotive and aerospace. Efficient and precise cutting capabilities drive this trend, attracting various industries.

North America is a key player in this market. A considerable percentage of laser cutting machines are manufactured here. This region emphasizes advanced technologies and innovation. However, challenges like high initial costs and the need for skilled labor persist. Many potential buyers hesitate, fearing the investment may not yield expected returns.

Emerging trends indicate a shift toward automation and integration with Industry 4.0 practices. Companies are increasingly seeking machines that offer connectivity and seamless data exchange. Despite this, some customers remain cautious due to concerns over training and transitioning. Striking a balance between advanced features and user-friendliness is crucial for manufacturers as they navigate this evolving landscape.

Key Features to Consider When Buying a Laser Cutting Machine

When considering a laser cutting machine, several key features come into play. One of the most important aspects is the machine's power. A higher wattage allows for cutting thicker materials more efficiently. However, too much power can lead to burnt edges, so finding a balance is crucial.

Another feature to evaluate is bed size. A larger bed accommodates bigger projects. However, larger machines can be cumbersome and expensive. Assess your typical project sizes before deciding.

Tips: Always consider future projects. Will you need flexibility? If yes, invest in a versatile machine. Don’t rush your decision. Reflect on your specific needs and budget constraints. Look for a machine that offers a good warranty. It’s better to invest a bit more for peace of mind.

2026 Best Laser Cutting Machine Features Comparison

Comparative Analysis: CO2 vs. Fiber Laser Cutting Technologies

Laser cutting machines utilize different technologies to deliver precise and efficient cutting. Two popular types are CO2 and fiber laser technologies. Understanding the differences between them can help you choose the right machine for your needs.

CO2 lasers use a mix of gases to produce a beam. They excel in cutting non-metal materials like wood and plastic. The beam produced is broad, allowing for finer details. However, they tend to be less efficient on metals. Fiber lasers, on the other hand, emit a concentrated beam. This allows for faster and keener cuts on metals. They are also more energy-efficient. Yet, they may struggle with thicker materials.

**Tips:** When choosing a laser cutter, consider the materials you’ll be working with. CO2 is great for softer substances, while fiber lasers are perfect for metals. Think about your long-term usage too. Investing in a machine that meets your growing needs is wise.

It’s essential to reflect on your budget. High-quality machines often come with a higher price tag. But lower-cost options might not fulfill your requirements. Balance your finances while ensuring you don’t compromise on quality.

Top Brands in Laser Cutting Machinery and Their Market Share

The laser cutting industry features several top brands that lead the market.

These companies dominate with innovative technology and performance. Many customers seek reliability

and precision. Understanding their market share can help with buying decisions.

In 2026, the market landscape will be competitive. Some brands continue to innovate, while others lag behind.

Consumers may feel overwhelmed by choices. Each brand has strengths and weaknesses.

Some excel in speed, while others shine in precision. This inconsistency can confuse potential buyers.

Furthermore, price points vary significantly across brands.

High-quality machines command higher prices.

However, cheaper models often sacrifice performance. This trade-off requires careful consideration.

Buyers should evaluate their specific needs.

A detailed study of reviews can also help clarify options. It's essential

to make informed decisions to avoid regrets later.

Customer Reviews and Ratings: Insights from Users in 2026

In 2026, laser cutting machines have gained significant traction among users across various industries. Customer reviews reveal a variety of experiences. Many users appreciate efficiency and precision. However, some report challenges with complex setups. This inconsistency highlights the need for user-friendly designs.

According to a recent industry report, around 68% of users found that ease of operation is a key factor when selecting a machine. Yet, a notable 20% expressed frustration with inadequate customer support. A machine's initial cost can be appealing, but hidden maintenance costs surfaced in several reviews. These insights assist potential buyers in making informed choices.

User ratings also emphasize the importance of material versatility. Many commend their machines for cutting a wide range of materials, including wood and metal. However, some users feel limited by certain machine specifications. These nuances can significantly influence production capabilities. Clearly, while laser cutting machines are praised for speed and accuracy, reflections on support and durability remain vital in the decision-making process.

Related Posts

-

Top Benefits of Using a Laser Cutting Machine for Your Projects

-

How to Choose the Right Laser Cutting Service for Your Project Needs

-

Top 10 Metal Cutting Laser Machines for Precision and Efficiency

-

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing

-

What is a Sheet Metal Laser Cutting Machine? Benefits and Applications Explained