Top 10 Best Metal Tubes for Your DIY Projects in 2023

In the ever-evolving landscape of DIY projects, the use of metal tubes has become increasingly popular among enthusiasts and professionals alike. Renowned metalworking expert John Anderson once stated, “Metal tubes provide unparalleled strength and versatility, making them an essential component in any DIY toolbox.” Their lightweight nature combined with durability makes them ideal for a multitude of applications, from structural supports to decorative elements.

As we dive into the top 10 best metal tubes for your DIY projects in 2023, it’s essential to understand the various types available in the market. Each type of metal tube brings its own unique properties, which can significantly impact the success of your project. Whether you are constructing a custom shelf or creating a unique lighting fixture, the right choice of metal tubes can make all the difference.

From aluminum to steel, the options are vast, and choosing wisely can elevate the quality of your build. Join us as we explore the best metal tubes available today, helping you navigate through styles, sizes, and finishes that can bring your creative visions to life. With the right information and tools, any DIYer can harness the potential of metal tubes to achieve stunning results.

Overview of Metal Tubes Suitable for DIY Projects

When it comes to DIY projects, selecting the right type of metal tube can significantly impact both the durability and aesthetics of your work. According to industry reports, metal tubing, particularly when fabricated from materials like aluminum and stainless steel, has seen a surge in popularity for various applications. The lightweight and corrosion-resistant properties of aluminum make it an ideal choice for projects requiring both strength and ease of handling. Meanwhile, stainless steel tubing offers exceptional resistance to rust and high temperatures, making it suitable for more demanding applications.

Moreover, standard sizes and thicknesses are widely available in the market, often specified in industry standards such as ASTM A500 or ASTM A53. A report from the Metal Industry Association indicates that the demand for metal tubes in DIY projects is expected to grow by approximately 5% annually through 2025. As DIY enthusiasts seek materials that can withstand outdoor conditions, the versatility of different metal tubes, including square, round, and rectangular shapes, allows for a wide range of creative designs. Whether crafting furniture, decorative elements, or functional constructions, understanding the properties and best applications of various metal tubes can empower DIYers to achieve effective and sustainable outcomes in their projects.

Factors to Consider When Choosing Metal Tubes

When selecting metal tubes for DIY projects, several key factors come into play that can significantly influence both the functionality and aesthetics of your final product. Firstly, material composition is crucial; common options include aluminum, stainless steel, and copper, each offering unique properties such as weight, corrosion resistance, and ease of manipulation. Aluminum, for instance, is lightweight and easy to work with, making it ideal for less demanding applications, while stainless steel provides superior strength and durability for more robust needs.

Another important consideration is the diameter and wall thickness of the metal tubes. These dimensions not only affect the structural integrity of the project but also the ease of cutting and joining the tubes. A thicker wall may enhance strength but could complicate the joining process, necessitating specialized tools or techniques. Additionally, the length of the tube should align with your project's specifications, as longer tubes can offer more versatility while shaping or bending. Lastly, one must also think about surface finish and the potential for aesthetic appeal; polished or anodized finishes can add a decorative element to your project, enhancing its overall appearance.

Top 10 Best Metal Tubes for Your DIY Projects in 2023

| Material Type | Diameter (mm) | Length (m) | Wall Thickness (mm) | Weight (kg) |

|---|---|---|---|---|

| Aluminum | 50 | 2 | 3 | 1.5 |

| Steel | 40 | 1.5 | 2 | 2.8 |

| Copper | 30 | 2.5 | 1 | 2.1 |

| Stainless Steel | 25 | 3 | 2 | 3.0 |

| Titanium | 20 | 1 | 1 | 1.0 |

| Mild Steel | 35 | 2 | 3 | 2.5 |

| Brass | 15 | 1.5 | 1 | 1.2 |

| Galvanized Steel | 60 | 3 | 2.5 | 4.0 |

| Nickel | 45 | 2.2 | 1.5 | 2.7 |

| Alloy Steel | 55 | 2.8 | 2 | 3.6 |

Top 10 Metal Tubes for Durability and Versatility

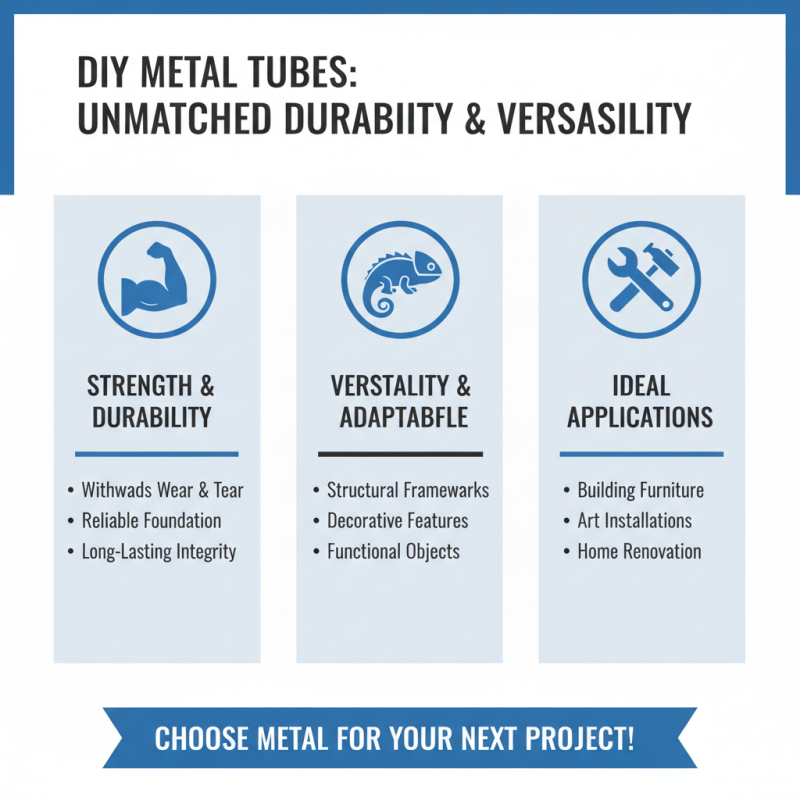

When it comes to DIY projects, choosing the right materials is crucial, and metal tubes stand out for their unmatched durability and versatility. The strength of metal allows it to withstand significant wear and tear, making it ideal for a variety of applications, from structural frameworks to decorative features. Whether you are building furniture, creating art installations, or making functional objects, metal tubes provide a reliable foundation that can handle day-to-day use without compromising integrity.

Moreover, the versatility of metal tubes is evident in their wide range of sizes, shapes, and finishes available in the market. This adaptability means that they can be easily incorporated into a myriad of projects, regardless of the complexity. Metal tubes can be cut, bent, and welded to fit specific design requirements, giving DIY enthusiasts the freedom to express their creativity while ensuring that the end product is not only visually appealing but also robust. Their resistance to rust and corrosion further enhances their appeal, making them a smart choice for both indoor and outdoor applications, ensuring longevity and aesthetic appeal across various projects.

Applications of Metal Tubes in Various DIY Projects

Metal tubes have become increasingly popular in DIY projects due to their strength, durability, and versatility. They can be used in various applications, from creating sturdy furniture to crafting decorative elements. For instance, metal tubes can serve as the framework for tables, chairs, and shelving units, providing an industrial aesthetic while ensuring structural integrity. Their resistance to corrosion makes them suitable for both indoor and outdoor projects, allowing creators to experiment with different designs without worrying about wear and tear.

In addition to furniture construction, metal tubes are frequently employed in functional applications such as plumbing and framing. Their rigid nature allows for precise measurements and easy assembly, making them ideal for DIY enthusiasts looking to tackle more complex tasks. Additionally, metal tubes can be utilized in garden projects, such as trellises or plant supports, adding both visual interest and functionality to outdoor spaces. With a plethora of sizes and finishes available, hobbyists can customize their projects to meet specific aesthetic and practical needs, highlighting the endless potential of metal tubes in the world of DIY.

Maintenance Tips for Metal Tubes in DIY Use

Maintaining metal tubes properly is crucial for ensuring their longevity and performance in DIY projects. According to industry reports, over 60% of failures in metal components result from inadequate maintenance practices. To prevent corrosion and prolong the lifespan of metal tubes, it’s essential to conduct regular inspections. Look for signs of rust or wear and make sure to clean any debris that may accumulate. Using protective coatings can significantly enhance the durability of metal tubes, providing a barrier against moisture and other corrosive agents.

Apart from routine checks, proper storage is equally important. When not in use, metal tubes should be stored in a dry, climate-controlled environment to minimize moisture exposure. Studies indicate that metal exposed to high humidity conditions can rust up to 50% faster than when stored in optimal conditions. Additionally, employing proper handling techniques during transportation can prevent dents and scratches, further preserving their structural integrity. By following these maintenance tips, DIY enthusiasts can ensure their metal tubes remain functional and reliable for a variety of projects in 2023 and beyond.

Top 10 Best Metal Tubes for Your DIY Projects in 2023

This bar chart illustrates the most popular metal tube materials used in DIY projects in 2023, based on their average usage frequency. The frequencies are represented on the Y-axis, while the different types of metal tubes are listed on the X-axis.

Related Posts

-

Exploring the Versatility of Metal Tubes: Innovative Applications You Didn't Know About

-

Exploring the Impact of Robotic Welding Technology on Manufacturing Efficiency and Quality Metrics

-

What is a Sheet Metal Laser Cutting Machine? Benefits and Applications Explained

-

How to Choose the Best Metal Cutting Laser Machine for Your Needs

-

2025 How to Choose the Best Industrial Equipment for Optimal Efficiency

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing