The Best 10 Sheet Metal Laser Cutting Machines for Precision Cutting

In the realm of modern manufacturing, the sheet metal laser cutting machine has emerged as a pivotal tool, revolutionizing the industry with unparalleled precision and efficiency. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach USD 5.5 billion by 2026, showcasing a compound annual growth rate (CAGR) of 6.6% from 2021 to 2026. The demand for accurate and high-speed cutting solutions in sectors such as automotive, aerospace, and electronics drives this growth, highlighting the importance of investing in state-of-the-art technology.

Sheet metal laser cutting machines utilize advanced laser technology to achieve intricate designs with minimal material waste, making them an ideal choice for manufacturers seeking to optimize their production processes. A study from ResearchAndMarkets indicates that the adoption of laser cutting technology can reduce operational costs by up to 15%, while improving overall product quality. As the industry evolves, it is crucial for professionals to understand the various options available in the market, ensuring they select the best machines that will meet their precision cutting needs in an increasingly competitive landscape.

Introduction to Sheet Metal Laser Cutting Machines

Sheet metal laser cutting machines have revolutionized the manufacturing industry, offering unparalleled precision and efficiency. These advanced tools utilize high-powered lasers to cut through various types of metal with remarkable accuracy, making them ideal for intricate designs and complex geometries. By focusing a concentrated beam of light onto the material, these machines can achieve clean cuts without the need for extensive finishing processes, thus reducing production time and waste.

The technology behind sheet metal laser cutting machines encompasses a variety of components, including the laser source, optics, and motion systems, all working in harmony to deliver precise results. Operators can program these machines with CAD software, allowing for seamless integration of design and production.

Furthermore, the automation capabilities of modern laser cutting machines enhance productivity by minimizing human error and increasing throughput, which is particularly beneficial for industries that require high-volume production runs. This innovation has made laser cutting a preferred method for fabricators looking to enhance their operational efficiency while maintaining excellent quality standards.

Key Features to Look for in Laser Cutting Technology

When selecting a sheet metal laser cutting machine, it's crucial to focus on key features that enhance precision and productivity. One of the foremost aspects is the power of the laser source. Reports indicate that machines with a laser output ranging from 1kW to 20kW are suitable for various materials and thicknesses. According to a recent industry analysis, increasing the power can significantly reduce cutting time while improving edge quality, which is especially important in high-demand sectors such as automotive and aerospace.

Another vital feature to consider is the cutting speed and the level of automation the machine offers. Advanced models are capable of achieving cutting speeds upwards of 30 meters per minute, enabling manufacturers to streamline production processes. Additionally, incorporating automation technologies, such as automated loading and unloading systems, has been shown to boost operational efficiency by up to 40%, as noted in the latest market trends report. This not only minimizes labor costs but also enhances safety by reducing manual handling.

Moreover, the precision of the cutting is largely dependent on the machine's CNC technology. High-quality CNC systems ensure that the laser beam maintains accuracy over extended periods, which is essential for intricate designs and high-quality fabrication. Industry studies indicate that machines equipped with sophisticated CNC technology can achieve tolerances as tight as ±0.05 mm, making them indispensable in precision-oriented applications. Thus, focusing on these key features will ensure that manufacturers choose the best laser cutting machines for their needs.

The Best 10 Sheet Metal Laser Cutting Machines for Precision Cutting

This chart displays the cutting speed (in inches per minute) and max material thickness (in mm) for the top sheet metal laser cutting machines. The data indicates the efficiency and capability of each machine in terms of precision and material handling.

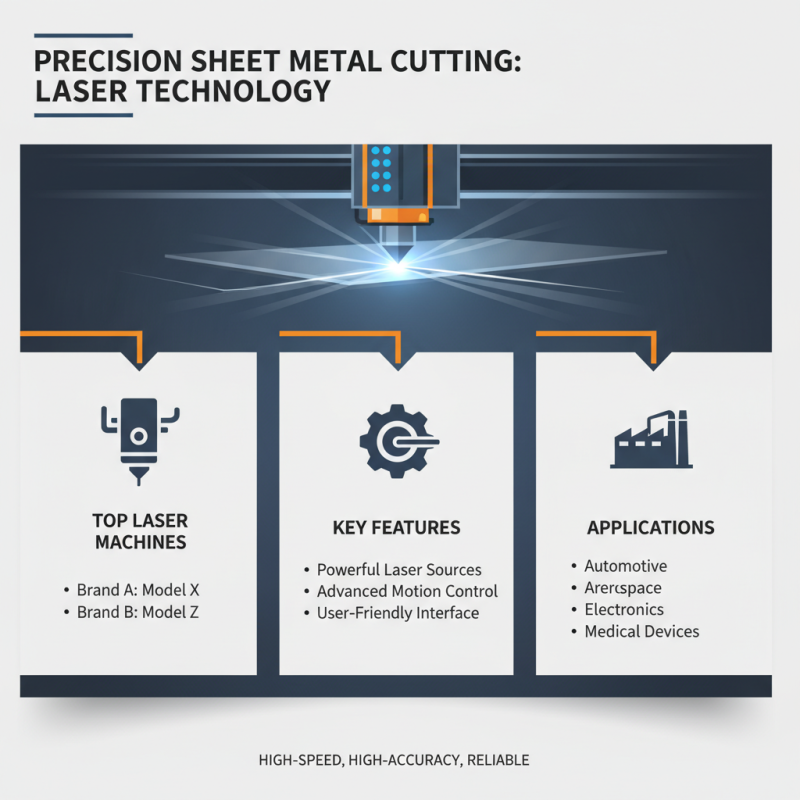

Top Brands and Models for Precision Laser Cutting

When it comes to precision sheet metal cutting, the choice of laser cutting machines plays a crucial role in achieving optimal results. Several top brands and models stand out for their advanced technology and reliability. These machines are engineered to deliver high-speed cutting with exceptional accuracy, making them suitable for a wide range of applications, from automotive to aerospace and beyond. Key features of the best machines often include powerful laser sources, advanced motion control systems, and user-friendly interfaces that enhance operational efficiency.

Tips: When selecting a laser cutting machine, consider the thickness of the materials you will be working with and the maximum cutting speed required. Additionally, ensure that the machine offers flexibility in terms of cutting complex shapes and designs. It's also beneficial to look for machines equipped with automation options, as they can significantly improve productivity and reduce labor costs.

Investing in a laser cutting machine involves more than just evaluating its cutting capabilities. Take into account the after-sales support offered by the manufacturer, including training and maintenance services. Regular upkeep and prompt assistance can maximize the performance and longevity of your machine, ensuring consistent, high-quality cuts for years to come.

Comparative Analysis of Performance and Efficiency

In the realm of sheet metal fabrication, precision and efficiency are paramount when selecting a laser cutting machine. A comparative analysis of the top ten machines reveals significant variations in performance metrics, which can greatly affect production outcomes. Factors such as cutting speed, accuracy, and material thickness handling are critical considerations. Machines equipped with advanced technology tend to offer higher precision, minimizing waste and maximizing the quality of cut edges. This allows manufacturers to stay competitive by reducing operational costs and ensuring better product consistency.

Additionally, energy efficiency plays a vital role in assessing the overall performance of these machines. Cutting systems that utilize power more effectively not only lower operational costs but also contribute to reducing the environmental footprint of manufacturing processes. In this comparative analysis, features such as beam quality, the type of laser used, and cooling mechanisms were evaluated to determine their impact on both efficiency and precision. The highest-performing machines excel in combining cutting speed with energy consumption, highlighting the need for manufacturers to prioritize these attributes in their selection process.

The Best 10 Sheet Metal Laser Cutting Machines for Precision Cutting - Comparative Analysis of Performance and Efficiency

| Machine Model | Cutting Speed (m/min) | Max Thickness (mm) | Efficiency (%) | Laser Type | Power (kW) |

|---|---|---|---|---|---|

| Model A | 25 | 20 | 90 | Fiber | 3 |

| Model B | 30 | 15 | 85 | CO2 | 4 |

| Model C | 20 | 25 | 92 | Fiber | 6 |

| Model D | 35 | 10 | 80 | Fiber | 5 |

| Model E | 28 | 18 | 88 | CO2 | 3.5 |

| Model F | 40 | 5 | 95 | Fiber | 8 |

| Model G | 22 | 30 | 89 | CO2 | 4.5 |

| Model H | 27 | 12 | 91 | Fiber | 5.5 |

| Model I | 24 | 14 | 86 | CO2 | 4 |

| Model J | 32 | 16 | 94 | Fiber | 7 |

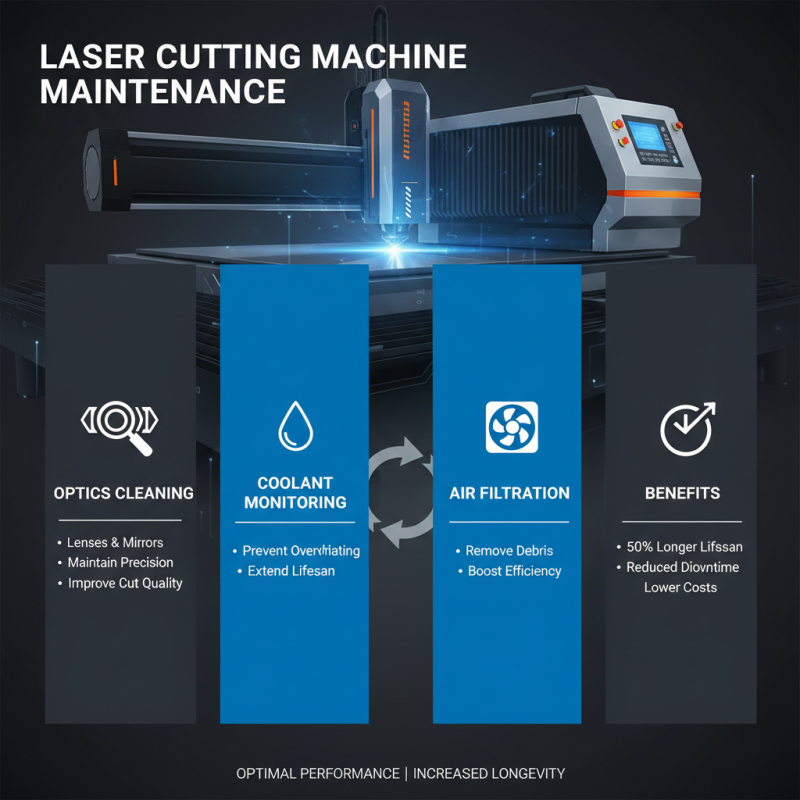

Maintenance and Care for Longevity of Laser Cutting Machines

Proper maintenance and care of laser cutting machines are crucial for ensuring their longevity and optimal performance. According to industry reports, regular maintenance can extend the lifespan of laser systems by up to 50%, significantly reducing downtime and operational costs. This includes routine cleaning of optical components, such as lenses and mirrors, which are essential for maintaining the precision of laser cutting. A clean optical path allows for effective energy delivery, thereby improving cutting speed and quality. Additionally, monitoring the coolant levels and ensuring that the air filtration system is functioning correctly can prevent overheating and the accumulation of debris, which could impact machine efficiency.

Moreover, preventative maintenance schedules are vital. The latest survey from the Laser Cutting Association indicates that businesses that implement systematic maintenance programs experience up to a 30% increase in production efficiency compared to those that do not. This encompasses periodic inspections and adjustments to the laser's alignment and focusing optics. Technicians should also perform software updates and calibrations to leverage the latest advancements in cutting technology. By adhering to these practices, manufacturers can not only enhance the longevity of their laser cutting machines but also ensure consistent output quality, meeting the demands of precision cutting in today’s competitive market.

Related Posts

-

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

-

How to Choose the Best Metal Cutting Laser Machine for Your Needs

-

Exploring the Impact of Robotic Welding Technology on Manufacturing Efficiency and Quality Metrics

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing

-

Top Tips for Efficient Metal Cutting Techniques and Tools

-

How to Maximize Your Efficiency with Almacam Software for Optimal Results