Why Choose a Metal Cutting Laser Machine for Your Manufacturing Needs?

In today's fast-paced manufacturing landscape, the demand for precision and efficiency has never been higher. As industries seek to optimize production processes, the adoption of advanced technologies has become essential. One such innovation is the metal cutting laser machine, which has transformed the way manufacturers approach metal fabrication. According to a report by Industry Research, the global laser cutting machine market is expected to grow significantly, projected to reach USD 5.1 billion by 2026, with a compound annual growth rate (CAGR) of 7.5%. This growth is driven by the increasing need for high-quality metal parts in various sectors, including automotive, aerospace, and electronics.

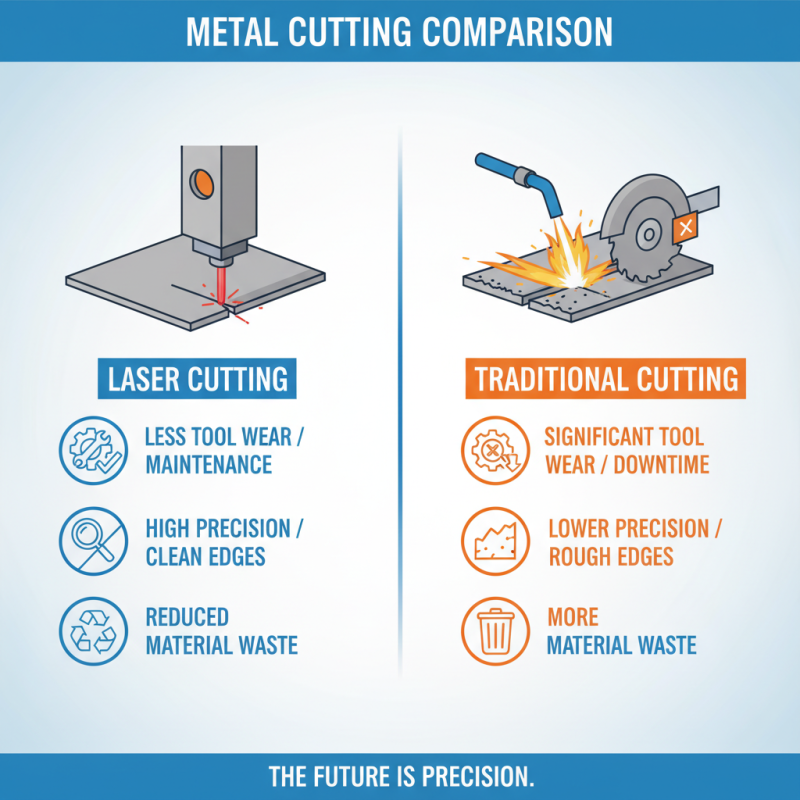

The advantages of utilizing a metal cutting laser machine extend beyond just speed; they encompass precision, versatility, and cost-effectiveness. Unlike traditional cutting methods, laser cutting technology offers unparalleled accuracy, enabling manufacturers to produce intricate designs with minimal material waste. A study by Mordor Intelligence reveals that the efficiency of laser cutting machines has led to a 30% reduction in production time, allowing businesses to enhance their output while maintaining quality standards. As manufacturers continue to navigate the competitive landscape, adopting a metal cutting laser machine presents a strategic opportunity to not only meet but exceed market demands, ultimately leading to increased profitability and sustainable practices.

Advantages of Using Metal Cutting Laser Machines in Manufacturing

Metal cutting laser machines have revolutionized manufacturing processes, offering significant advantages that enhance productivity and precision. One of the most notable benefits is the unparalleled accuracy they provide. The focused laser beam can cut intricate designs with tolerances that are often difficult to achieve with traditional cutting methods. This precision minimizes material waste and reduces the need for extensive post-processing, ultimately saving time and reducing costs.

Another important advantage is the versatility of laser cutting technology. It can effectively handle a variety of metals, including stainless steel, aluminum, and brass, making it suitable for diverse manufacturing applications. Coupled with the ability to operate at high speeds, metal cutting laser machines enable manufacturers to produce complex components quickly and efficiently. This adaptability not only meets the demands of custom orders but also allows businesses to keep pace with rapidly changing market trends while maintaining high quality in their products.

Advantages of Using Metal Cutting Laser Machines in Manufacturing

The bar chart below illustrates the key advantages of using metal cutting laser machines in manufacturing processes, highlighting aspects such as precision, speed, versatility, and cost-effectiveness.

Key Features to Look for in Laser Cutting Technology

When selecting a metal cutting laser machine for manufacturing, understanding the key features of laser cutting technology is essential. One critical feature is cutting speed, which can significantly affect productivity. According to a report by the International Laser Manufacturing Conference, modern CO2 and fiber lasers can achieve cutting speeds up to 30 meters per minute on materials such as stainless steel, considerably reducing operational time and costs. Additionally, the accuracy of laser cutting is another paramount consideration. High-quality laser machines can maintain tolerances within ±0.1 mm, allowing manufacturers to produce intricate designs without compromising on quality.

Another important feature to consider is versatility in material compatibility. Cutting machines that can handle various materials—such as aluminum, copper, and plastic—provide greater flexibility for manufacturers. A study from the Laser Institute of America highlights that fiber lasers, in particular, have shown a capability to cut reflective materials efficiently, which broadens the types of projects a manufacturer can undertake. Finally, ease of operation and maintenance should not be overlooked; user-friendly interfaces and automated settings can streamline processes, enabling even less experienced operators to achieve high-quality results. In a competitive manufacturing landscape, investing in a laser cutting machine with these key features can lead to enhanced production efficiency and product quality.

The Impact of Laser Machines on Production Efficiency

The advent of laser technology has significantly transformed the landscape of manufacturing, especially in the realm of metal cutting. Laser machines excel in precision and speed, offering manufacturers the ability to produce intricate designs with minimal material wastage. This efficiency in production results not only in time savings but also in reduced operational costs, making laser cutting a preferred choice for industries aiming to optimize their workflows.

Moreover, the impact of laser machines extends beyond mere speed and accuracy. The versatility of laser cutting capabilities allows for the handling of various materials, providing manufacturers with the flexibility to experiment with different applications without needing extensive reconfiguration of equipment. Additionally, the consistency and reliability of laser technology ensure a higher standard of quality in finished products, which translates to improved customer satisfaction and retention. By integrating laser machines into their production processes, manufacturers can enhance their competitiveness and adapt more readily to changing market demands.

Comparing Metal Cutting Lasers with Traditional Cutting Methods

When comparing metal cutting lasers with traditional cutting methods, several key distinctions emerge that highlight the advantages of laser technology. Traditional methods, such as plasma or mechanical cutting, generally involve significant physical force and can create considerable wear and tear on tools. This can lead to higher maintenance costs and downtime. In contrast, laser cutting is a non-contact process, reducing the risk of tool damage and leading to extended equipment lifespan. The precision of laser cutting also eliminates the need for secondary processing, ensuring cleaner edges and less material wastage.

Furthermore, metal cutting lasers offer unparalleled versatility in terms of material compatibility and thicknesses they can handle. Traditional cutting methods often require different setups or machines depending on the material type and thickness, whereas a laser machine can effortlessly switch between materials like steel, aluminum, and even more complex alloys. This adaptability makes laser cutting an optimal choice for manufacturers looking to streamline operations and enhance productivity, as it allows for a single machine to fulfill multiple roles in a manufacturing process.

Cost Considerations for Investing in Laser Cutting Machines

When considering investments in manufacturing technologies, the cost implications of metal cutting laser machines are crucial. According to a report by Research and Markets, the market for laser cutting machines is projected to reach $5.52 billion by 2025, indicating a robust growth trajectory driven by efficiency and precision. The initial investment in a metal cutting laser machine may be higher than traditional cutting methods, but the long-term savings are significant. Laser machines offer faster processing times, reduced material waste, and lower operational costs due to their energy efficiency and less need for maintenance.

Operating costs are a vital aspect of long-term profitability. A study by IBISWorld highlighted that companies utilizing laser cutting technology could reduce their labor costs by up to 30% compared to other cutting methods. This reduction can be attributed to the automation capabilities of laser machines, which require fewer operators and less manual intervention. Furthermore, the lifespan of laser equipment is often longer than that of traditional machines, resulting in lower replacement costs and increased return on investment. Given these financial advantages, investing in a metal cutting laser machine is increasingly seen as a strategic move for manufacturing firms looking to enhance productivity and competitive edge.

Related Posts

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing

-

What is a Sheet Metal Laser Cutting Machine? Benefits and Applications Explained

-

How to Maximize Your Efficiency with Almacam Software for Optimal Results

-

Top 10 Tips for Sheet Metal Bending Techniques You Need to Know

-

Top 10 Best Metal Tubes for Your DIY Projects in 2023

-

2025 Top 5 Water Jet Cutting Innovations You Need to Know