How to Choose the Right Industrial Sheet Metal for Your Project Needs

When embarking on a manufacturing or construction project, one critical component that often demands thorough consideration is the choice of industrial sheet metal. This material forms the backbone of many structural and functional elements in various industries, from automotive to aerospace, and even in architectural applications. Choosing the right type of industrial sheet metal not only impacts the performance and durability of the final product but also affects cost-efficiency and production timelines.

To make an informed decision, it is essential to understand the various types of sheet metals available, their properties, and how these relate to the specific requirements of your project. Factors such as thickness, alloy composition, and surface treatments can drastically influence the suitability of the material for your intended application. By carefully assessing these attributes and aligning them with your project needs, you can ensure that you select the most appropriate industrial sheet metal, thus paving the way for successful outcomes. Whether you are looking for strength, corrosion resistance, or malleability, comprehending the nuances of industrial sheet metal will be instrumental in achieving your project goals.

Understanding the Different Types of Industrial Sheet Metal Materials

When selecting industrial sheet metal for your project, it’s crucial to understand the various materials available, as each offers unique properties and advantages. Common types include aluminum, steel, and stainless steel.

Aluminum is lightweight and resistant to corrosion, making it ideal for applications where weight reduction is essential. Steel, particularly carbon steel, is known for its strength and affordability, making it suitable for a wide range of industrial applications.

Stainless steel, on the other hand, combines strength with excellent resistance to rust and corrosion, making it perfect for environments exposed to moisture or chemicals.

Tips: When choosing your material, consider the specific environmental conditions your metal will face. If your project will be exposed to high humidity or corrosive substances, stainless steel or treated aluminum may be the best options. For projects requiring structural integrity without excessive weight, opt for high-strength steel.

Additionally, take into account the fabrication process you intend to use, as different metals can have different machining and welding characteristics.

Understanding these distinctions can greatly influence the success of your project. Always assess the mechanical properties, aesthetics, and potential lifespan of the material. Don’t hesitate to consult with suppliers or fabricators to ensure you select the right type of industrial sheet metal tailored to your specific needs.

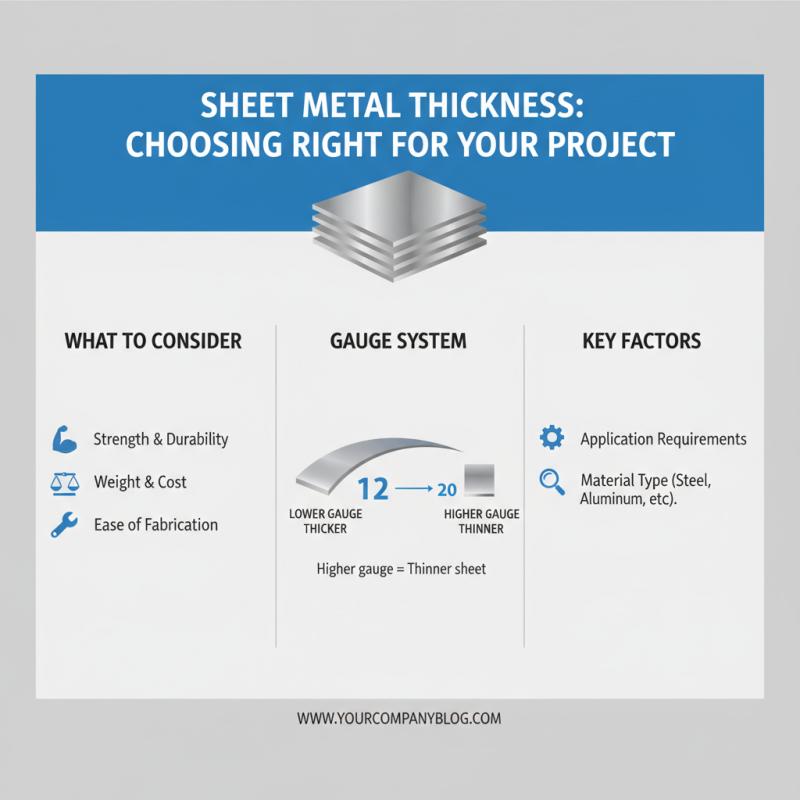

Key Factors to Consider When Choosing Sheet Metal Thickness

When selecting the right sheet metal for your project, one of the crucial factors to consider is the thickness of the material. The thickness not only affects the strength and durability of your product but also influences its weight, cost, and ease of fabrication. Typically, sheet metal thickness is measured in gauge numbers, with a higher gauge indicating a thinner sheet. For instance, a 20-gauge sheet is thinner than an 18-gauge sheet. Understanding the specific requirements of your application will help you determine the appropriate thickness.

Tips: Consider the environment where the sheet metal will be used. For applications exposed to harsh conditions, such as extreme temperatures or moisture, selecting a thicker gauge may be necessary to ensure longevity and withstand wear. On the other hand, if your project is lightweight and requires flexibility, a thinner gauge may suffice.

Another essential aspect to evaluate is the load the sheet metal needs to support. If the metal will bear heavy loads or withstand significant pressure, choosing a thicker gauge will provide the necessary strength and prevent deformation. Conversely, for decorative or non-load bearing applications, thinner sheets can be more economical and sufficient. Evaluate your project’s demands carefully to make an informed decision.

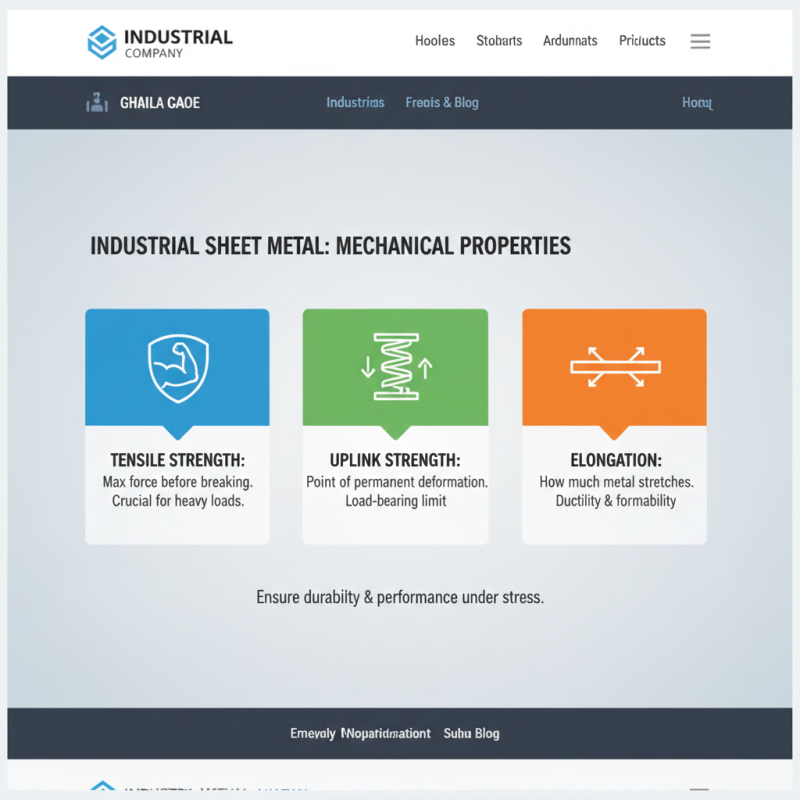

Evaluating the Mechanical Properties of Sheet Metal for Durability

When selecting industrial sheet metal for your project, evaluating the mechanical properties is crucial to ensure durability and performance under varying conditions. Key mechanical properties to consider include tensile strength, yield strength, and elongation, as they indicate how the material will behave when subjected to stress. Tensile strength, which measures the maximum amount of force the metal can withstand without breaking, is essential for projects involving heavy loads or harsh environments. A material with high tensile strength will likely endure significant stress without failure.

Additionally, the yield strength of sheet metal determines the point at which the material begins to deform permanently. For applications that require precise shapes or fittings, a higher yield strength is beneficial, as it minimizes the risk of structural changes during use. Lastly, elongation reflects the material's ability to stretch before breaking, indicating its ductility. Ductile materials can absorb impacts and accommodate slight misalignments during assembly, making them suitable for a wide range of industrial applications. Considering these mechanical properties will help you select the right sheet metal that meets both functional and durability requirements for your project.

Comparing Cost-Effectiveness and Performance of Various Metal Alloys

When selecting industrial sheet metal for your project, the comparison between cost-effectiveness and performance of various metal alloys becomes crucial. For instance, widely used metals like aluminum, steel, and stainless steel each have distinct characteristics impacting both budget and application efficiency. Aluminum is known for its lightweight nature and excellent corrosion resistance, making it an ideal choice for applications requiring reduced weight and durability. In contrast, carbon steel offers strength and longevity at a lower cost, albeit with a higher tendency for corrosion. According to a recent study by the Metal Market Report, carbon steel comprises approximately 70% of the sheet metal market due to its favorable cost-performance ratio.

**Tip:** Always assess the working environment and end-use of the sheet metal to determine which alloy will provide the best performance without exceeding your budget. For example, if your project entails exposure to harsh chemicals or extreme temperatures, investing in stainless steel may ultimately save money through reduced corrosion-related maintenance costs.

Performance metrics also play a vital role in the selection process. The tensile strength, malleability, and thermal conductivity of aluminum are particularly noteworthy, with values typically around 310 MPa, enabling manufacturers to optimize fabrications for unique applications. As reported by the International Metal Association, while aluminum may be costlier upfront than other materials, its lifecycle advantages may provide overall savings, proving its value in long-term projects.

**Tip:** Conduct a lifecycle cost analysis before finalizing your choice of metal. This will help you understand not just the initial investment but also the potential maintenance and replacement costs over time, ensuring a more informed decision that aligns with both performance requirements and budget constraints.

How to Choose the Right Industrial Sheet Metal for Your Project Needs

| Metal Alloy | Cost per Square Foot ($) | Durability (years) | Corrosion Resistance | Weight (lbs per sq ft) |

|---|---|---|---|---|

| Aluminum 5052 | $4.00 | 25 | Excellent | 0.098 |

| Stainless Steel 304 | $3.50 | 30 | Good | 0.08 |

| Mild Steel | $2.00 | 15 | Poor | 0.1 |

| Titanium Grade 5 | $12.00 | 50 | Excellent | 0.16 |

| Galvanized Steel | $3.00 | 20 | Fair | 0.094 |

Assessing Industry Standards and Regulations for Sheet Metal Selection

When selecting industrial sheet metal for a project, understanding the relevant industry standards and regulations is crucial. Compliance with these standards ensures not only the structural integrity of the final product but also the safety of those involved in its manufacturing and use. Typically, organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide guidelines that cover various properties of sheet metal, including thickness, tensile strength, and corrosion resistance. By familiarizing yourself with these standards, you can make informed decisions that meet both functional requirements and legal obligations.

Additionally, it is important to consider any specific regulations that may apply to the type of industry or application for which the sheet metal is being used. Industries such as construction, automotive, and aerospace have stringent standards that dictate materials' performance under various conditions. For instance, in construction, compliance with local building codes ensures that the materials used will sustain expected loads and resist environmental stressors. Understanding these regulations not only aids in choosing the appropriate material but also mitigates the risk of project delays and legal issues arising from non-compliance.

Comparison of Common Sheet Metal Types in Industrial Applications

Related Posts

-

Exploring Advanced Metal Welding Techniques: Boosting Efficiency and Quality in Industrial Applications

-

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

-

How to Choose the Best Metal Cutting Laser Machine for Your Needs

-

2025 How to Choose the Best Industrial Equipment for Optimal Efficiency

-

Top 10 Best Metal Tubes for Your DIY Projects in 2023

-

Top 10 Metal Cutting Laser Machines for Precision and Efficiency