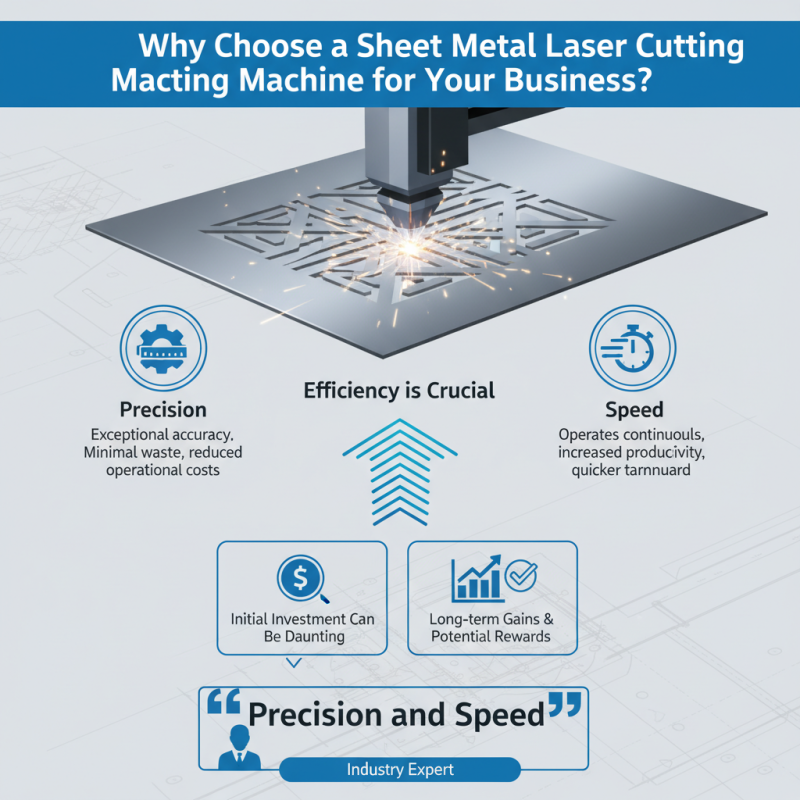

Why Choose a Sheet Metal Laser Cutting Machine for Your Business?

In today's competitive manufacturing landscape, efficiency is crucial. A sheet metal laser cutting machine stands out as a transformative tool for businesses. Industry expert John Smith, a leader in laser technology, once said, "Investing in a sheet metal laser cutting machine is investing in precision and speed." This statement captures the essence of why companies are increasingly embracing this technology.

The sheet metal laser cutting machine offers exceptional accuracy. It can cut intricate designs with minimal waste, which is vital in reducing operational costs. Speed is another advantage. These machines can operate continuously, significantly increasing productivity. Businesses that adopt this technology often see quicker turnaround times. However, the initial investment can be daunting. Not every company is ready for such an expense.

Despite the challenges, many firms recognize the potential rewards. Choosing the right machine is a critical decision. It requires weighing immediate costs against long-term gains. The decision to integrate a sheet metal laser cutting machine could redefine operational capabilities. It encourages a thoughtful approach to modernization in manufacturing.

Advantages of Using Laser Cutting Technology in Sheet Metal Processing

Laser cutting technology has revolutionized sheet metal processing. It offers precision unmatched by traditional methods. This technology uses focused laser beams to cut through various metal types effortlessly. The resulting cuts are clean and require minimal finishing, saving time and resources.

In addition to precision, laser cutting reduces material waste. The narrow kerf of laser cuts means less scrap metal. This aspect is not only cost-effective but also environmentally friendly. Smaller, more intricate designs are possible. However, machine operation requires skilled personnel. Training is essential to maximize the technology's potential.

Flexibility is another advantage. Laser machines can easily switch between materials and thicknesses. Custom projects can be completed without significant downtime. Yet, initial setup and programming can be complex. Errors in this stage can lead to delays. Constant improvement and adaptation are necessary for optimal performance.

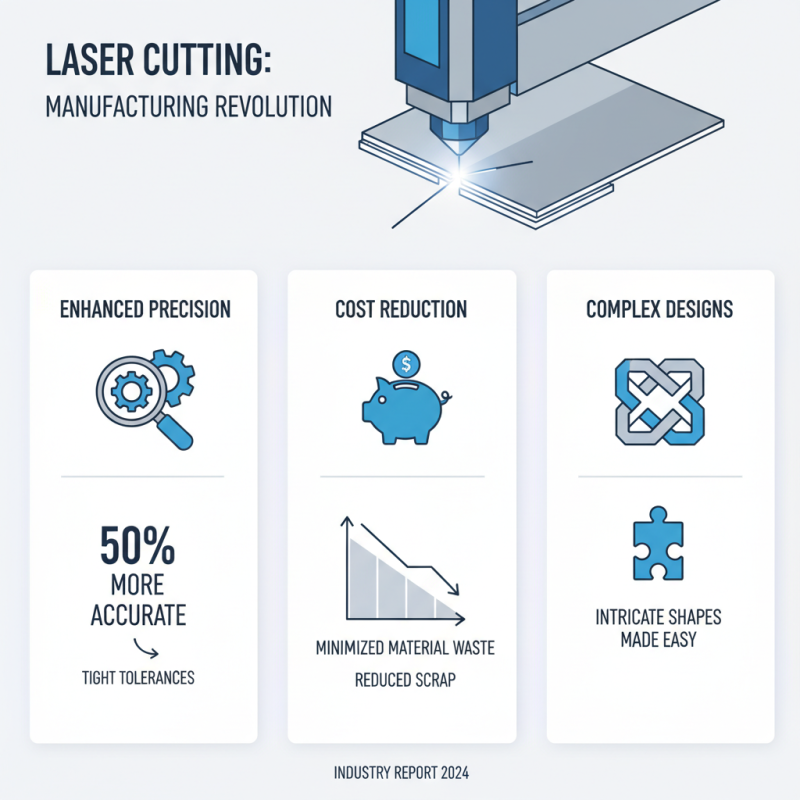

How Laser Cutting Improves Efficiency and Accuracy in Manufacturing

Laser cutting has transformed manufacturing, especially in sheet metal processing. A recent industry report indicates that laser cutting enhances precision by up to 50%. This level of accuracy minimizes material wastage. In turn, it reduces costs for businesses. With tight tolerances achieved through laser technology, manufacturers can produce complex shapes with ease.

The speed of laser cutting cannot be overlooked. According to a study, laser cutting machines can operate at speeds of 100 inches per minute. This efficiency allows companies to meet tighter deadlines and increase production rates. However, the initial investment in these machines is significant. Many firms can hesitate due to the cost, but the long-term savings from reduced labor and materials often justify this.

Additionally, integrating laser cutting with other technologies can present challenges. Companies must ensure their workforce is properly trained. Not all employees may adapt quickly. This need for training can slow down initial implementation. However, embracing these advancements can lead to significant improvements. Overall, the efficiency and accuracy provided by laser cutting are undeniable.

Cost-Effectiveness of Investing in a Laser Cutting Machine

Investing in a sheet metal laser cutting machine can be a game changer for many businesses. A recent industry report indicates that laser cutting reduces production costs by approximately 20-30%. This cost-effectiveness stems from reduced material waste and faster cutting speeds. Businesses can handle complex designs that traditional methods struggle with. However, initial investment costs can seem high.

Yet, the long-term savings can easily offset this. For instance, some studies reveal that companies experience a 15% increase in productivity after implementing laser technology. The reduced labor needed for intricate cuts also contributes to these savings. Many companies find that enhanced precision leads to higher-quality output, which can justify the initial expense. Still, not all businesses may see immediate returns.

In the end, companies should evaluate their specific needs. While laser cutting offers many advantages, the effectiveness varies. It's crucial to consider existing workflows. Some may not fully adapt to these advanced machines without thoughtful integration. Balancing cost with potential growth requires careful consideration and reflection.

Why Choose a Sheet Metal Laser Cutting Machine for Your Business? - Cost-Effectiveness of Investing in a Laser Cutting Machine

| Feature | Benefits | Cost Savings (%) | Investment Return Time (Years) |

|---|---|---|---|

| Precision Cutting | Less material wasted; higher quality finishing | 20% | 1.5 |

| Speed | Increased production rates; shorter lead times | 30% | 2 |

| Versatility | Ability to cut a variety of materials and thicknesses | 25% | 1.8 |

| Automation | Reduced labor costs; minimized human error | 15% | 1.2 |

| Minimal Setup Time | Faster job turnaround; more efficient workflow | 10% | 1.0 |

Applications of Sheet Metal Laser Cutting Across Various Industries

Sheet metal laser cutting machines are transforming various industries. These tools excel in precision and speed, crucial for modern manufacturing. Their applications span automotive, aerospace, electronics, and construction sectors. In the automotive industry, laser cutting ensures precise parts for vehicle assembly, improving safety and performance.

In aerospace, the need for lightweight materials is paramount. Laser cutting allows designers to create complex shapes with minimal waste. Electronics rely on this technology for intricate circuit boards and casings.

However, despite the benefits, some businesses struggle with the initial investment costs. It's a challenge to balance upfront expenses with long-term savings.

Additionally, the learning curve can be steep. Staff need training to operate these machines effectively. Mistakes in setup can lead to material waste and increased costs. Yet, those who navigate these challenges often find that laser cutting enhances efficiency significantly. The potential for innovation is vast, and companies must be ready to adapt.

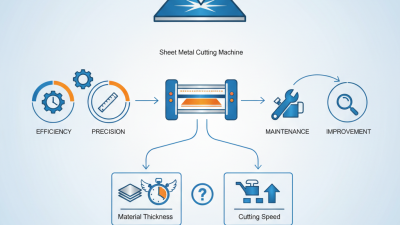

Factors to Consider When Choosing a Laser Cutting Machine for Your Business

When selecting a laser cutting machine, businesses must weigh various factors. Precision is crucial. In Industries, a 2019 report showed that laser cutting can achieve tolerances of ±0.005 inches. This accuracy is key for intricate designs. Additionally, efficiency plays a role; machines can cut materials like steel, aluminum, and copper at speeds averaging 600 inches per minute. Faster cutting means quicker project turnaround.

Energy consumption is another concern. Advanced lasers can consume 40% less power than older models. This translates to lower operating costs over time. However, not all machines are friendly to the environment. Investing in machines with better energy ratings can demonstrate commitment to sustainability, which can enhance brand image.

Lastly, consider maintenance needs. Some machines require frequent part replacements, while others boast longer lifespans with less upkeep. An overly complex machine may lead to operational frustrations. The decision should reflect the firm’s commitment to reliability and continuous improvement. The wrong choice can lead to costly downtimes. This balance between cutting-edge technology and practical functionality should drive your investment choices.

Related Posts

-

How to Choose the Right Laser Cutting Service for Your Project Needs

-

Top 10 Metal Cutting Laser Machines for Precision and Efficiency

-

Top 10 Tips for Sheet Metal Bending Techniques You Need to Know

-

What is Laser Cutting and How Does It Work for Various Materials

-

What is Sheet Metal Cutting? Techniques, Benefits, and Applications Explained

-

Why Choose a Sheet Metal Cutting Machine for Your Manufacturing Needs?