How to Choose the Best Metal Cutting Laser Machine for Your Needs

Choosing the right metal cutting laser machine is a critical decision for anyone involved in metal fabrication and manufacturing. With advancements in technology, the market now offers a plethora of options, each varying in features, capabilities, and price points. Whether you are a small business looking to expand your production capabilities or a large enterprise aiming for increased efficiency, understanding what to consider when selecting a metal cutting laser machine can make a substantial difference in your operational success.

In this guide, we will explore key factors to help you identify the best metal cutting laser machine that meets your specific needs. From assessing the types of materials you'll be working with, to evaluating power requirements and customization options, making an informed choice is crucial. We will also highlight the significance of considering maintenance, support services, and overall cost-effectiveness to ensure a long-term investment that aligns with your production goals. Embracing the right technology not only enhances productivity but also fosters innovation in your metalworking projects.

Understanding Different Types of Metal Cutting Laser Machines

When selecting a metal cutting laser machine, understanding the various types available is crucial. There are mainly two categories of laser cutting technologies: CO2 and fiber lasers. CO2 lasers utilize a gas mixture to generate a high-powered beam, making them suitable for cutting thick materials and non-metal surfaces.

On the other hand, fiber lasers offer higher efficiency and speed, especially for thin metal sheets. They have rapidly gained popularity due to their ability to handle a wide range of metals with precision and lower operational costs.

Another important consideration when choosing a laser cutting machine is the power and speed specifications. As the industry trends toward higher power and speed capabilities, machines that can adapt to these advancements are becoming increasingly relevant. Some contemporary models are designed to perform multi-tasking operations, addressing varying manufacturing needs while enhancing productivity. Understanding these distinctions and advancements helps businesses make informed decisions tailored to their specific requirements in metal cutting applications.

Evaluating Your Specific Cutting Requirements and Applications

When selecting a metal cutting laser machine, it is crucial to evaluate your specific cutting requirements and applications. A recent industry report by Research and Markets indicates that the global industrial laser market is projected to reach USD 8.5 billion by 2025, largely driven by advancements in laser technology and increasing demand across various sectors. Understanding the material types, thicknesses, and intricacies involved in your projects can significantly influence your choice of laser system. For instance, CO2 lasers are often preferred for cutting non-metal materials, whereas fiber lasers excel in high-speed metal cutting due to their efficiency and versatility.

Additionally, consider the operational environment and expected production volume. A study from MarketsandMarkets highlights that manufacturers are increasingly adopting automation in laser cutting processes, which not only enhances productivity but also improves precision. For cutting applications like prototyping, a lower wattage machine may suffice, while heavy industrial operations may require a high-powered fiber laser cutter capable of handling thick metals with ease. Assessing these factors will help ensure that the metal cutting laser machine you choose aligns with your operational goals and maximizes efficiency.

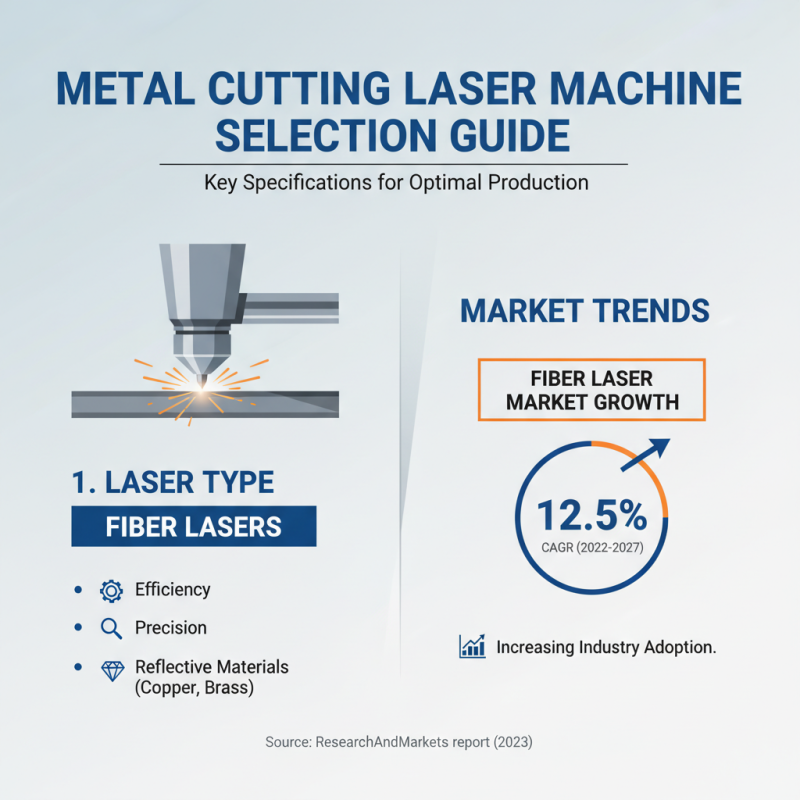

Key Specifications to Consider When Selecting a Laser Machine

When selecting a metal cutting laser machine, several key specifications should be taken into account to ensure that the system meets your specific production needs. One of the most crucial factors is the laser type. Fiber lasers are recognized for their efficiency and precision, especially when cutting reflective materials like copper and brass. According to a recent report by ResearchAndMarkets, the fiber laser market is expected to grow at a CAGR of 12.5% between 2022 and 2027, emphasizing their rising adoption in the industry.

Another significant specification is power output, which directly affects cutting speed and material thickness capabilities. Power typically ranges from 500 watts to several kilowatts; higher wattage allows for cutting through thicker materials more quickly. It’s also essential to consider the machine's work area size to accommodate the dimensions of the materials you will be processing. Furthermore, factors like cutting speed and precision, often measured in mm/min, can drastically influence production efficiency.

**Tips:** Always match the machine’s specifications with your production volume and material types. Also, ensure the machine has robust software compatibility for efficient integration into your current workflow. Conducting a thorough cost-benefit analysis regarding operating and maintenance costs is also critical to ensure long-term viability.

Comparing Costs: Budgeting for Your Metal Cutting Laser Investment

When considering the costs of investing in a metal cutting laser machine, it is essential to analyze the current market landscape and the impact of external factors like the COVID-19 pandemic. The laser cutting machine market has been experiencing growth, driven by advancements in technology and an increasing demand across various industries. Fiberglass lasers, CO2 lasers, and solid-state lasers offer distinct advantages and varying price points, making it crucial for buyers to understand their specific needs and budget constraints.

Furthermore, the emergence of automation in laser cutting technology has led to the development of semi-automatic and robotic systems, which can significantly enhance productivity but may come at a higher initial investment. Each technology type and functionality will also cater to different end-user sectors, such as automotive, aerospace, and manufacturing, further complicating the decision-making process. Prospective buyers must evaluate not only the upfront costs but also the long-term operational expenses, maintenance, and potential return on investment to ensure they choose the best option for their unique requirements.

How to Choose the Best Metal Cutting Laser Machine for Your Needs - Comparing Costs: Budgeting for Your Metal Cutting Laser Investment

| Machine Type | Power (W) | Cutting Thickness (mm) | Price Range (USD) | Recommended For |

|---|---|---|---|---|

| Fiber Laser | 1000 - 3000 | 10 - 25 | $30,000 - $100,000 | Industrial Manufacturing |

| CO2 Laser | 25 - 150 | 5 - 15 | $10,000 - $30,000 | Small Business, Hobbyists |

| Nd:YAG Laser | 100 - 500 | 1 - 10 | $15,000 - $50,000 | Medical Applications, Jewelry Making |

| Ultrafast Laser | 200 - 1000 | 0.1 - 5 | $50,000 - $200,000 | Advanced Manufacturing, Micromachining |

Maintenance and Support: Ensuring Longevity of Your Equipment

When considering a metal cutting laser machine, the longevity of the equipment is heavily influenced by effective maintenance practices. Just as in other industries, such as medical equipment and fire apparatus, a proactive approach to maintenance can significantly enhance the lifespan and reliability of metal cutting machines. Regular checks, timely repairs, and adherence to maintenance schedules not only prevent potential breakdowns but also optimize operational efficiency, ensuring your investments serve you well over time.

Support systems play a crucial role in the maintenance of machinery, allowing operators to maximize equipment performance. A comprehensive maintenance strategy should include access to technical support, spare parts, and ongoing training for operators. By investing in these support mechanisms, you can reduce downtime and improve the overall productivity of your metal cutting operations. The shift towards predictive maintenance solutions further underscores the importance of anticipating issues before they arise, enabling you to proactively manage the health of your laser machinery and extend its operational lifespan.

Laser Cutting Machine Maintenance Factors

Related Posts

-

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

-

Exploring the Impact of Robotic Welding Technology on Manufacturing Efficiency and Quality Metrics

-

How to Maximize Your Efficiency with Almacam Software for Optimal Results

-

Unlocking Efficiency How Nesting Software Revolutionizes Material Cutting Processes

-

2025 Top 5 Water Jet Cutting Innovations You Need to Know

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing