Top Tips for Efficient Metal Cutting Techniques and Tools

Efficient metal cutting is a critical aspect of various industrial processes, playing a vital role in manufacturing, construction, and fabrication. As industries continue to evolve, the demand for precision and speed in metal cutting has surged, necessitating the adoption of advanced techniques and tools. Understanding the basics of metal cutting is essential for professionals seeking to enhance productivity while maintaining high-quality standards.

With numerous techniques available, ranging from traditional methods to modern innovations, it is crucial for practitioners to stay informed about the latest developments in metal cutting. This guide aims to provide top tips that can help streamline the metal cutting process, reduce waste, and improve overall efficiency. Whether you are a seasoned expert or a newcomer to the field, exploring these tips will arm you with the knowledge necessary to select the right tools and techniques for various applications, ultimately leading to superior results in your projects.

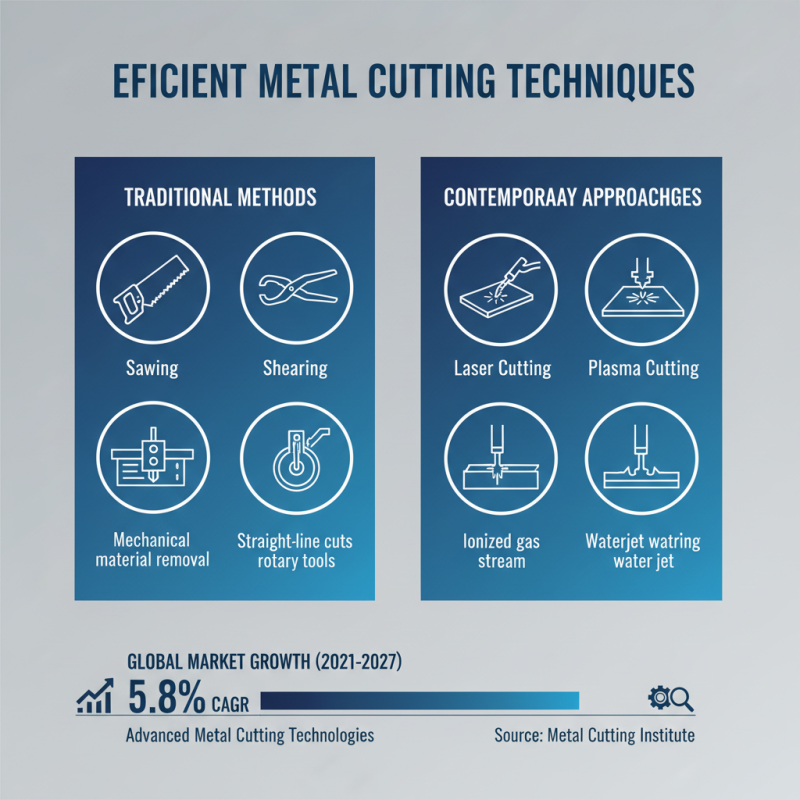

Understanding Different Metal Cutting Techniques

When it comes to efficient metal cutting, understanding the various techniques available is crucial for optimizing production processes. Commonly used methods include traditional techniques such as sawing, shearing, and machining, as well as contemporary approaches like laser cutting, plasma cutting, and waterjet cutting. According to a report by the Metal Cutting Institute, the global market for advanced metal cutting technologies is expected to grow at a CAGR of 5.8% from 2021 to 2027, highlighting the increasing demand for precise and efficient metal cutting solutions.

Laser cutting, for instance, is known for its accuracy and ability to cut complex shapes with minimal thermal distortion. This technique operates by directing a high-powered laser beam onto the metal surface, achieving clean cuts suitable for intricate designs. On the other hand, plasma cutting is favored for its speed and ability to cut through thick metals, making it ideal for fabrication industries. Based on industry studies, plasma cutting can reduce cutting time by up to 30% compared to conventional methods, thus enhancing overall productivity.

Moreover, waterjet cutting stands out for its versatility, allowing for the processing of a wide range of materials without introducing heat-affected zones, which can compromise the integrity of certain metals. Recent analyses indicate that 30% of manufacturers are now adopting multi-axis waterjet systems to enhance their cutting capabilities. By comprehensively understanding these cutting techniques and their respective advantages, businesses can make informed decisions that lead to improved efficiency and cost-effectiveness in their metal processing operations.

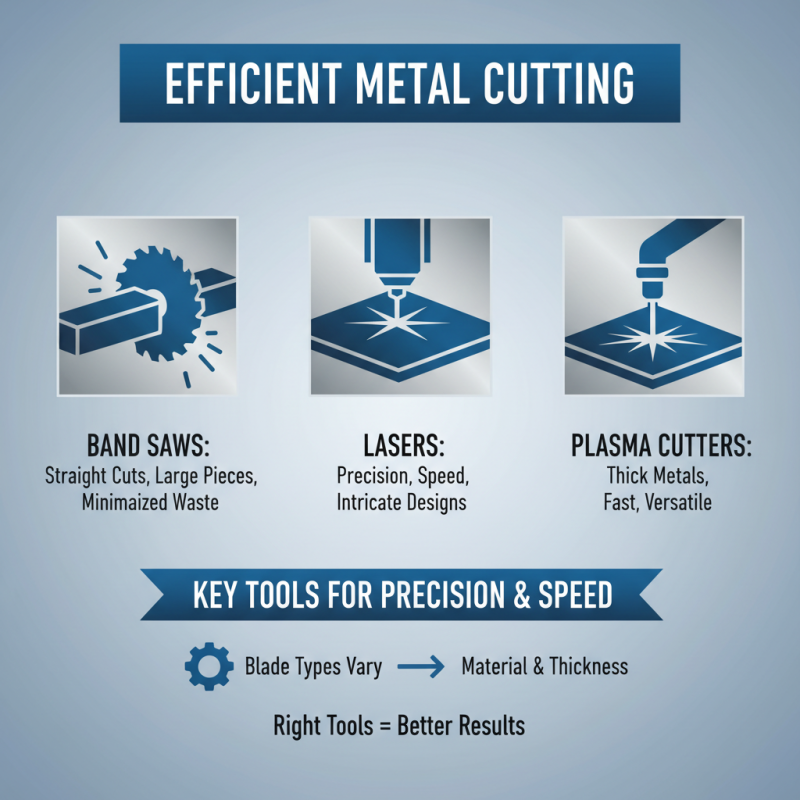

Essential Tools for Efficient Metal Cutting

When it comes to efficient metal cutting, having the right tools is crucial for achieving precision and speed. Various tools cater to different cutting techniques, such as saws, lasers, and plasma cutters. Band saws, for instance, are ideal for making straight cuts in larger metal pieces, providing clean finishes while minimizing waste. These tools are equipped with various blade types depending on the material and thickness, making them versatile for a range of applications.

In addition to traditional saws, modern technologies such as laser cutting systems offer unparalleled accuracy for complex designs and tight tolerances. Laser cutters generate clean cuts with minimized heat-affected zones, reducing the risk of warping the material. Meanwhile, plasma cutting is another technique that excels in cutting thick metals quickly and efficiently. This method uses a high-velocity stream of ionized gas to melt and blow away the metal, allowing for rapid processing of heavy materials. Investing in a combination of these essential tools can significantly enhance productivity and precision in metalworking projects.

Factors Affecting Metal Cutting Efficiency

Several factors significantly affect metal cutting efficiency, influencing the overall performance of cutting techniques and tools. One of the primary elements is the material being cut. Different metals possess varying hardness, toughness, and thermal conductivity, which directly impact the cutting speed, tool wear, and the quality of the finished surface. Understanding the specific properties of the metal is crucial, as it allows for the selection of appropriate cutting speeds and feeds to maximize efficiency and reduce tool degradation.

Another important factor is the geometry of the cutting tool itself. The design features, such as the cutting edge angle, rake angle, and clearance angle, play vital roles in determining the effectiveness of the cutting process. Optimizing these parameters can lead to enhanced chip formation and heat dissipation, ultimately improving the cutting performance and extending tool life. Additionally, the choice of cutting fluids or lubrication can drastically affect heat management and chip removal, further influencing the cutting efficiency and the overall productivity of metalworking operations.

Top Tips for Efficient Metal Cutting Techniques and Tools

This chart illustrates the efficiency of different metal cutting techniques based on various factors, such as speed, tool wear, and material type. The data represents relative cutting efficiency on a scale of 1 to 100.

Safety Tips for Metal Cutting Processes

When engaging in metal cutting processes, safety must be the priority to prevent accidents and injuries. First, it is essential to wear appropriate personal protective equipment (PPE). This includes safety goggles to protect the eyes from flying debris, gloves to safeguard the hands from sharp edges, and hearing protection if working with loud machinery. Additionally, wearing steel-toed boots provides foot protection, while flame-resistant clothing is advisable when working with high temperatures to prevent burns.

Another critical aspect of safety is ensuring that all tools and machinery are in proper working condition before use. Regular maintenance checks and inspections can help identify potential issues that could pose risks during operation. Furthermore, using tools that are suitable for the specific type of metal being cut aids in maintaining control and reducing the likelihood of accidents. Operators should also be aware of their surroundings and ensure that the workspace is clear of any obstacles that could cause slips or falls. Lastly, following all operational guidelines provided with the machinery significantly enhances safety during metal cutting tasks.

Maintenance and Care for Cutting Tools

Maintaining and caring for cutting tools is essential for achieving efficient metal cutting and prolonging the life of your equipment. Regular maintenance not only enhances performance but also ensures safety during operation. One important tip is to keep your cutting tools clean and free from debris. Regularly inspect the tools for any signs of wear or damage. A clean tool performs better and reduces the risk of unexpected failures.

Another key aspect of tool care involves proper lubrication. Using the right lubricant can minimize friction, reduce heat buildup, and prevent unnecessary wear. Always check the manufacturer's guidelines for recommended lubrication frequency and types. Furthermore, consider employing a rotation schedule for your cutting tools. Rotating tools allows each item to rest and reduces the chances of overheating, which can significantly impact their lifespan.

Lastly, storage plays a crucial role in maintaining tool integrity. Tools should be stored in a dry, clean environment, away from excessive moisture and contaminants that could lead to rust and corrosion. Utilizing toolboxes or specialized storage solutions not only protects the edges but also organizes the workspace, making it easier to locate and access tools efficiently. With these maintenance tips, you can ensure your cutting tools remain in top condition for optimal performance.

Top Tips for Efficient Metal Cutting Techniques and Tools - Maintenance and Care for Cutting Tools

| Cutting Technique | Recommended Tools | Maintenance Tips | Effectiveness Rating (1-5) |

|---|---|---|---|

| Laser Cutting | CO2 Laser Cutter | Keep lenses clean; check alignment regularly. | 5 |

| Plasma Cutting | Plasma Cutter | Change consumables frequently; maintain air filtration. | 4 |

| Waterjet Cutting | Waterjet Machine | Regularly check water filters; flush the system often. | 4 |

| CNC Machining | CNC Milling Machine | Lubricate moving parts; update software regularly. | 5 |

| Band Saw Cutting | Horizontal Band Saw | Keep blades sharp; check tension regularly. | 4 |

Related Posts

-

Exploring the Future of Metal Cutting Technologies: Trends, Innovations, and Market Insights for 2024

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing

-

Maximize Fabrication Efficiency: The Rise of Sheet Metal Nesting Software in 2025

-

How to Choose the Best Metal Cutting Laser Machine for Your Needs

-

What is a Sheet Metal Laser Cutting Machine? Benefits and Applications Explained

-

Unlocking Efficiency How Nesting Software Revolutionizes Material Cutting Processes