10 Essential Metal Working Tips for Beginners to Enhance Skills

Metal working is a fascinating craft that combines art and engineering. For beginners, the journey can be daunting yet rewarding. According to the American Welding Society, the metalworking industry is projected to grow by 4% annually. Mastering the basics is key to ensuring progress in this field.

John Smith, an expert in metal working with over 20 years of experience, insists, “Practice makes perfect, but understanding the fundamentals is critical.” Beginners often overlook the importance of safety protocols. Improper use of tools can lead to accidents that halt progress. Learning to appreciate the nuances can transform a novice into a skilled metalworker.

Setting up a organized workspace may seem trivial, yet it profoundly affects productivity. Many newcomers underestimate this aspect, blocking their creative flow. Embracing the small details can make a world of difference. As you explore metal working, take the time to reflect on what works best for you and your style.

Understanding Basic Metalworking Tools and Their Uses

Understanding basic metalworking tools is crucial for beginners. Without a solid grasp of these tools, projects can become frustrating. Common tools include hammers, saws, and files. Each tool has its unique purpose. For example, hammers can shape metal but may also result in dents. Start slowly and learn to manage that impact.

One essential tip is to keep your workspace organized. It helps minimize errors and improves safety. Disorganized spaces can lead to accidents. A cluttered bench makes it hard to find tools. Allocate a spot for each tool and return them after use. This habit fosters efficiency.

Another crucial aspect is safety gear. Always wear gloves and goggles. However, even with protection, mistakes may happen. Sometimes, a piece of metal might slip or a tool may slip from your hand. Learning to be mindful of these risks enhances your skills over time. Embrace minor mishaps as part of the learning process.

Safety Precautions Every Beginner Metal Worker Should Follow

Safety is paramount in metalworking, especially for beginners. According to a 2021 industry report, nearly 40% of new metalworkers reported experiencing minor injuries due to neglecting safety protocols. Always wear protective gear. Safety glasses and gloves are your first line of defense. A simple slip can lead to serious injuries or accidents.

Tip 1: Keep your workspace organized. A cluttered area can cause distractions and accidents. Ensure tools are stored properly. Regularly clean up scrap metal and debris to prevent tripping hazards.

Tip 2: Understand your tools. Each tool has specific safety precautions. For instance, using a welding machine requires knowledge of fire hazards. Don’t rush. Take time to study the equipment. Beginners often underestimate the need for this preparation.

Emerging data stresses the importance of safety training. Nearly 60% of accidents can be mitigated with proper education. Regularly attend workshops or seek guidance. A single oversight can result in consequences that affect your work and well-being. Prioritizing safety ensures a productive and enjoyable experience in metalworking.

10 Essential Metal Working Tips for Beginners to Enhance Skills - Safety Precautions Every Beginner Metal Worker Should Follow

| Tip Number | Tip | Description | Safety Precaution |

|---|---|---|---|

| 1 | Wear Proper Safety Gear | Always wear gloves, goggles, and a face shield. | Protects against flying debris and sharp edges. |

| 2 | Understand Your Tools | Familiarize yourself with each tool’s purpose and operation. | Prevention of misuse and accidents. |

| 3 | Keep Work Area Clean | Maintain a tidy workstation free of clutter. | Reduces the risk of tripping and accidents. |

| 4 | Use Appropriate Lighting | Ensure your workspace is well-lit to see your work clearly. | Helps in preventing errors and accidents. |

| 5 | Practice Makes Perfect | Regularly practice using different metalworking techniques. | Builds confidence and skill over time. |

| 6 | Measure Twice, Cut Once | Ensure accuracy by measuring dimensions before cutting. | Prevents waste of material and potential accidents. |

| 7 | Secure Your Work | Always secure materials before cutting or grinding. | Prevents movement that can lead to injuries. |

| 8 | Be Aware of Your Surroundings | Stay alert to people and objects around your workspace. | Avoids collisions and distractions. |

| 9 | Learn from Others | Seek guidance from experienced metalworkers. | Gains valuable insights and tips to improve skills. |

| 10 | Take Breaks | Regularly step away to rest your mind and eyes. | Prevents fatigue and maintains focus on tasks. |

Essential Techniques for Cutting and Shaping Metal Accurately

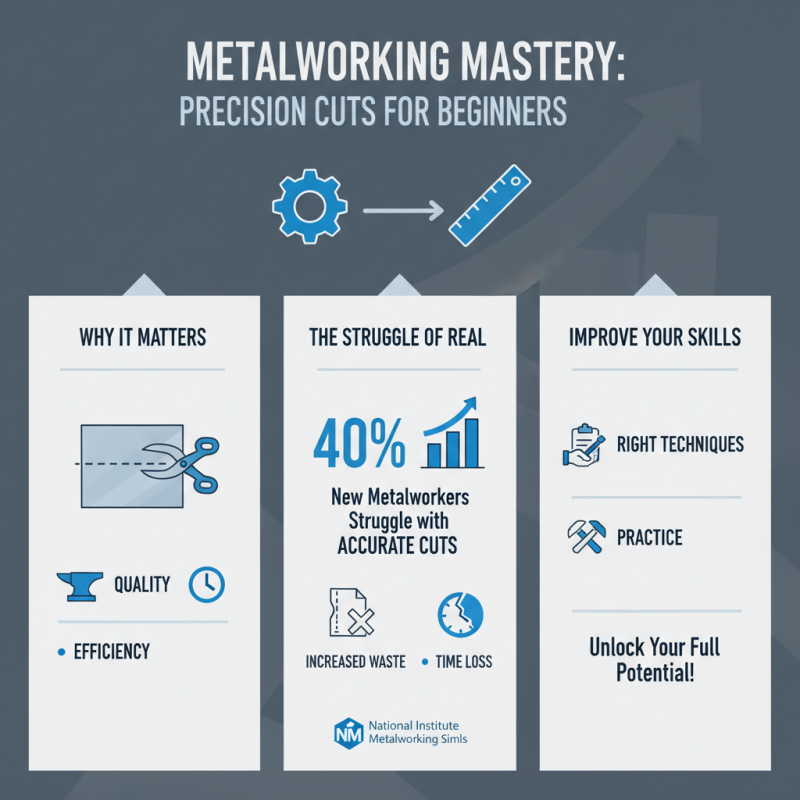

Cutting and shaping metal accurately is essential for any beginner in metalworking. Precision in these processes directly affects the quality of the final product. According to a recent survey from the National Institute of Metalworking Skills, nearly 40% of new metalworkers struggle with accurate cuts. This results in increased waste and time lost. Skills in cutting can be greatly improved with the right techniques and practice.

Utilizing tools such as band saws, shears, and plasma cutters requires an understanding of their capabilities. For example, a band saw is great for intricate cuts but demands patience and steady hands. Beginners often underestimate the amount of setup time needed. A quick adjustment can mean the difference between a clean edge and a rough finish. Moreover, using a grinding wheel can refine those edges, but improper use can lead to overheating, warping the metal. Reflecting on these mistakes is crucial for growth in metalworking.

Shaping metal involves techniques like bending and forming. Each technique has its challenges. The Metal Fabrication Industry Report states that approximately 30% of fabricated parts fail quality checks due to shape inaccuracies. Practicing different techniques helps develop muscle memory. Metalworking is as much about skill as it is about learning from errors. Knowing the limitations of each method can guide beginners toward perfecting their craft.

Tips for Properly Joining Metals Through Welding and Soldering

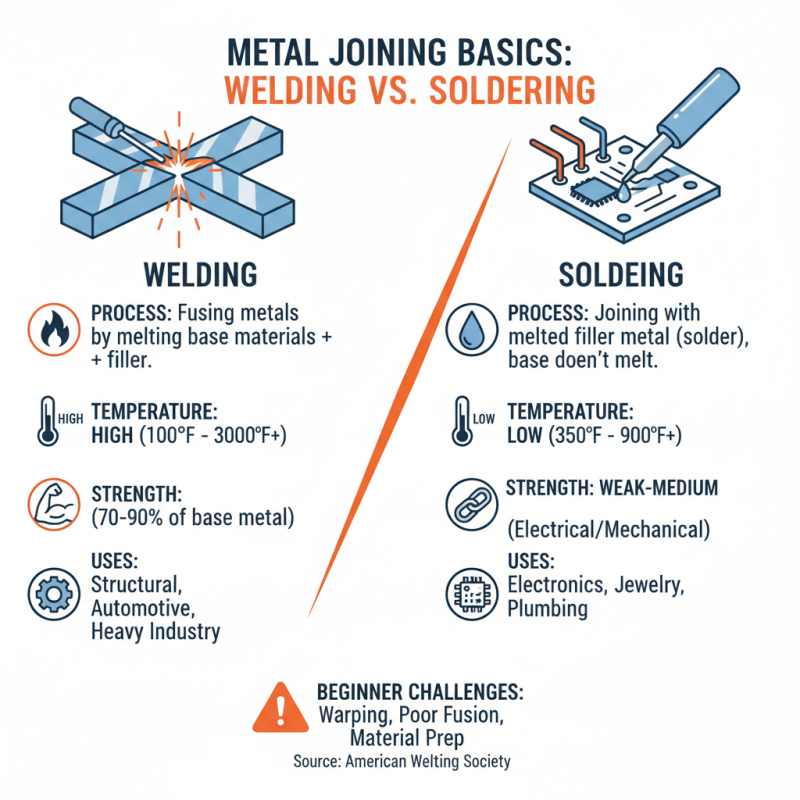

Welding and soldering are critical techniques for joining metals. Beginners often face challenges with both methods. Understanding the basics is crucial. According to the American Welding Society, a solid weld can yield strength between 70% to 90% of the base material. This means even a small mistake can weaken the joint significantly.

When welding, ensure the metals are clean. Remove rust and contaminants. The weld pool must flow smoothly. Many beginners struggle with proper heat settings. Overheating can cause warping or burn-through. A study noted that 25% of failed welds are due to improper heat control.

Soldering requires a different approach. It involves using a filler material with a lower melting point. The joint must be heated adequately without overheating the components. Some may rush, leading to poor adhesion. Monitoring the solder flow is essential. Inexperienced hands may create a cold joint without realizing it. Aim for a shiny, smooth finish. An imperfect joint can lead to future repairs and frustrations. Remember, practice is the key to mastering these skills.

Maintaining and Caring for Your Metalworking Tools for Longevity

Proper maintenance of your metalworking tools is crucial for their longevity. Regular cleaning is essential. After every use, wipe down tools to remove dust, metal shavings, or residue. A small brush can help reach tight spaces. Avoid leaving tools dirty for extended periods, as this can lead to rust and deterioration.

Keep an eye on your tools’ sharpness. Dull blades can make your work harder and less precise. It’s frustrating when a tool fails to perform as expected. Invest time in learning how to sharpen your tools correctly. This practice not only saves money but also builds your skills. Remember that even a simple tool requires attention.

Store your tools properly to prevent damage. Using toolboxes or racks can keep them organized. It’s easy to overlook this aspect, but it makes a difference. Protect sensitive parts from wear and tear. If tools are frequently dropped or knocked, they can become misaligned. Reflect on your workspace habits; improvement can enhance both productivity and safety.

Related Posts

-

How to Choose the Right Industrial Sheet Metal for Your Project Needs

-

Exploring the Future of Metal Cutting Technologies: Trends, Innovations, and Market Insights for 2024

-

Exploring Advanced Metal Welding Techniques: Boosting Efficiency and Quality in Industrial Applications

-

How to Choose the Best Tools for Metal Cutting in Your Workshop

-

Exploring the Impact of Robotic Welding Technology on Manufacturing Efficiency and Quality Metrics

-

Top 10 Tips for Sheet Metal Bending Techniques You Need to Know