What is Laser Cutting and How Does It Work for Various Materials

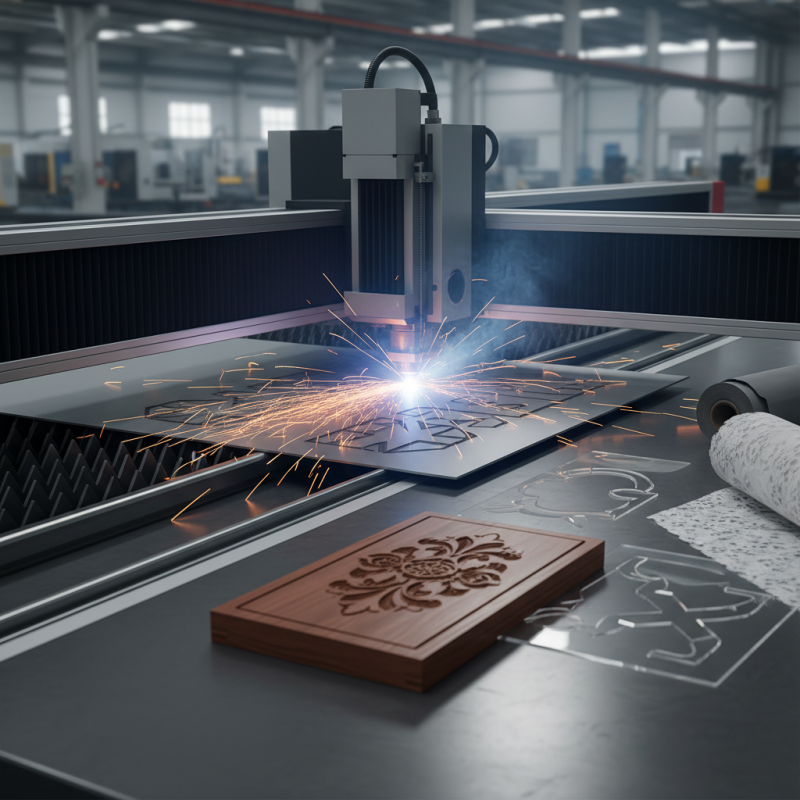

Laser cutting is a technologically advanced method that employs focused beams of light to precisely cut through various materials. This innovative process has gained immense popularity across multiple industries due to its accuracy, efficiency, and versatility. At its core, laser cutting works by directing a high-powered laser beam onto the material surface, which melts, burns, or vaporizes the material, resulting in a clean and precise cut. This technique is not only fast but also ensures minimal waste, making it an environmentally friendly option compared to traditional cutting methods.

The applications of laser cutting are diverse, spanning from manufacturing and engineering to fashion and art. Whether it's cutting intricate designs in sheet metal, engraving detailed patterns on wood, or creating precise components in aerospace engineering, the flexibility of laser cutting allows for a wide range of material compatibility. Additionally, advancements in laser technology continue to enhance the capabilities and efficiency of laser cutting, further solidifying its importance in modern manufacturing processes. As industries evolve and new materials emerge, understanding how laser cutting works can provide valuable insights into its benefits and potential applications.

What is Laser Cutting?

Laser cutting is a highly precise manufacturing process that utilizes focused laser beams to cut materials with remarkable accuracy. This technology operates by directing a high-powered laser onto the material, which either melts, burns, or vaporizes the material to create a cut. The laser cutting process is extensively employed in various industries, including automotive, aerospace, and electronics, due to its ability to produce intricate designs with minimal kerf width, resulting in less material waste. According to a report by Markets and Markets, the global laser cutting machine market is projected to reach $5.71 billion by 2025, highlighting its increasing importance in industrial applications.

One of the primary advantages of laser cutting is its versatility. It can effectively process a wide range of materials, including metals, plastics, wood, and fabrics. Laser cutting machines can adjust their power and speed settings to accommodate different thicknesses and densities, making them suitable for both thick and thin materials. For example, lasers can cut stainless steel up to several inches thick while also being able to carve intricate patterns into materials like acrylic or leather. A study from Grand View Research estimates that the metal cutting segment alone will witness significant growth, driven by the rising demand for precision in manufacturing and fabrication processes. This adaptability not only enhances productivity but also allows for creative possibilities that are increasingly sought after in custom manufacturing and prototyping.

Laser Cutting Efficiency by Material Type

The Science Behind Laser Cutting Technology

Laser cutting is a modern technology that utilizes focused beams of light to cut through various materials with exceptional precision. The science behind laser cutting lies in the process of converting light energy into thermal energy, allowing the laser to melt, burn, or vaporize the material in its path. According to a market report by Smarter Shows, the global laser cutting market is projected to reach $8 billion by 2025, underscoring its growing significance across industries such as automotive, aerospace, and manufacturing.

The operation of laser cutting involves several critical components, including the laser source, lens system, and the material being processed. Typically, CO2 or fiber lasers are employed, with CO2 lasers being ideal for thicker materials while fiber lasers excel in cutting metals due to their high efficiency. As the laser beam is directed onto the material, it creates a small, concentrated point of heat that allows for intricate designs and clean edges, with cutting speeds often reaching 50 meters per minute.

Tips: When implementing laser cutting technology, it’s essential to select the appropriate laser type based on the material characteristics. Additionally, optimizing the settings such as speed, power, and focus can significantly enhance cutting quality and efficiency. Always ensure proper ventilation and safety measures are in place, especially when working with materials that release fumes when cut.

Different Types of Lasers Used in Cutting

Laser cutting technology employs various types of lasers, each suited for different materials and applications. The most common lasers used in cutting processes include CO2 lasers, fiber lasers, and solid-state lasers. CO2 lasers are particularly effective for cutting non-metal materials like wood, plastic, and textiles, thanks to their longer wavelength which allows for better absorption by these materials. They are known for their high power output, enabling efficient cuts and intricate designs.

On the other hand, fiber lasers utilize a solid-state medium to produce a laser beam, making them ideal for cutting metals such as stainless steel, aluminum, and brass. The shorter wavelength of fiber lasers provides increased precision and speed when working with thin materials, and they are also more energy-efficient compared to CO2 lasers. Solid-state lasers, while less common, are another option that can be tailored for specific cutting tasks, particularly in industrial applications where high energy density is required. Each laser type brings unique advantages, significantly affecting the quality and efficiency of the cutting process across various materials.

Materials Suitable for Laser Cutting

Laser cutting is a precise and versatile technique that can be used on various materials, making it a popular choice in industries from manufacturing to art. Materials suitable for laser cutting include metals, plastics, wood, fabrics, and even glass. The effectiveness of laser cutting on these materials depends on their thickness, composition, and the specific type of laser used.

For metals such as stainless steel, aluminum, and brass, laser cutting allows for intricate designs with clean edges. The high energy of the laser beam effectively vaporizes the metal without causing much thermal distortion. On the other hand, materials like wood and acrylic can be cut with excellent precision, leaving smooth edges. This capability is especially appreciated in furniture design and decorative arts.

**Tips:** When selecting a material for laser cutting, consider the thickness of the material and its ability to withstand high temperatures. Ensure that the laser cutting service you choose can accommodate the specific material requirements to achieve the best results. Additionally, for intricate designs, a material with a smooth surface quality will yield a more precise cut. Always test a small sample of the material first to determine how it reacts to the laser, which can help in avoiding undesirable outcomes during the cutting process.

Applications of Laser Cutting Across Industries

Laser cutting technology has transformed various industries by offering precise and efficient cutting solutions. In manufacturing, laser cutting is extensively utilized for cutting metals, plastics, and composites. Its accuracy allows for intricate designs without the need for extensive tooling, making it ideal for creating components in the aerospace and automotive sectors. This precision not only improves product quality but also minimizes material waste, contributing to greater efficiency in production processes.

In addition to manufacturing, laser cutting finds applications in the textile and fashion industries. Designers leverage this technology to create detailed patterns and clean edges on fabrics, allowing for innovative and complex designs that would be difficult to achieve with traditional methods.

Moreover, the wood industry benefits from laser cutting by enabling intricate engravings and precise cuts on wooden materials, enhancing the aesthetic appeal of furniture and decorative items. Overall, laser cutting serves as a versatile tool across various sectors, enhancing creativity and functionality in product design and manufacturing.

Related Posts

-

How to Choose the Right Laser Cutting Service for Your Project Needs

-

Top 10 Metal Cutting Laser Machines for Precision and Efficiency

-

Top Benefits of Using a Laser Cutting Machine for Your Projects

-

Exploring the Versatility of Metal Tubes: Innovative Applications You Didn't Know About

-

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

-

Exploring the Future of Metal Cutting Technologies: Trends, Innovations, and Market Insights for 2024