Top 10 Metal Cutting Laser Machines for Precision and Efficiency

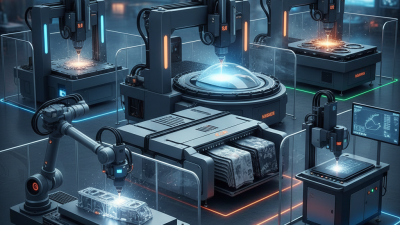

In the realm of modern manufacturing, precision and efficiency are paramount, especially when it comes to metal fabrication. The emergence of advanced metal cutting laser machines has revolutionized the industry, enabling manufacturers to achieve intricate designs and high-speed cutting with remarkable accuracy. These machines utilize laser technology to cut through various metals, offering a level of precision that traditional cutting methods simply cannot match. As industries continue to demand higher performance and better quality, the significance of selecting the right metal cutting laser machine has never been more crucial.

As we explore the top 10 metal cutting laser machines, we aim to provide insights into their capabilities, features, and applications. Each machine on our list exemplifies the latest advancements in laser cutting technology, designed to enhance productivity while maintaining tight tolerances. From small-scale workshops to large manufacturing facilities, understanding the strengths and functionalities of these machines can help business owners make informed decisions. Ultimately, investing in a high-quality metal cutting laser machine can lead to improved operational efficiency, reduced material waste, and enhanced overall performance in metalworking tasks.

Top Considerations for Choosing a Metal Cutting Laser Machine

When selecting a metal cutting laser machine, several critical factors come into play to ensure precision and efficiency in your operations. First and foremost, the machine's power output should match your specific cutting requirements. Higher wattage generally allows for the processing of thicker materials and results in cleaner cuts, but it also demands a more significant investment. Therefore, understanding the types of materials you will be working with and their respective thicknesses is essential for making an informed decision.

Another vital consideration is the laser technology itself. CO2 and fiber lasers are two common types, each with its advantages. CO2 lasers are excellent for cutting non-metal materials and achieve high-quality results on various metals, while fiber lasers are known for their speed and efficiency when working with reflective metals like aluminum and copper. Assessing the material types and thicknesses you frequently encounter will help determine the best technology for your needs.

Additionally, consider the machine's bed size and configuration, which can impact your workflow and productivity. A larger bed size accommodates bigger sheets and can lead to less material waste. Lastly, the integration of advanced features such as automation, user-friendly interfaces, and software compatibility can greatly influence operation efficiency and ease of use. Evaluating these factors will allow you to identify a metal cutting laser machine that meets your performance expectations while remaining within your budget.

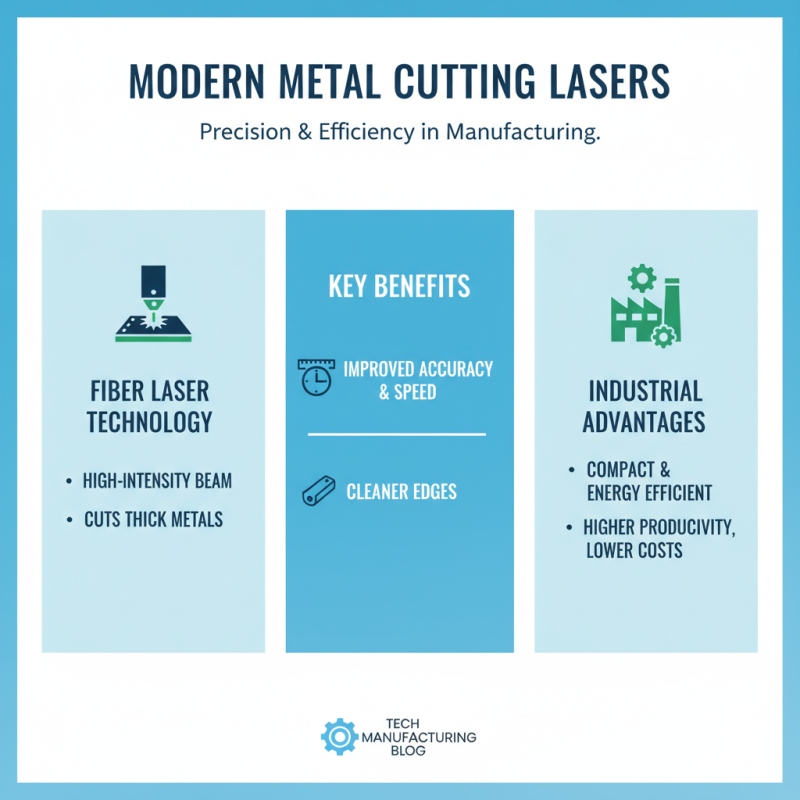

Key Technologies in Modern Metal Cutting Lasers and Their Advantages

Modern metal cutting lasers utilize advanced technologies that significantly enhance precision and efficiency in manufacturing processes. One of the key technologies is fiber laser technology, which offers a high-intensity beam that can cut through thick metal sheets with remarkable accuracy. This method not only improves cutting speed but also produces cleaner edges, reducing the need for additional finishing processes. The compact size and energy efficiency of fiber lasers make them an ideal choice for various industrial applications, enabling companies to achieve higher productivity levels while minimizing operational costs.

Another significant advancement in metal cutting lasers is the integration of automation and smart technologies. These systems often feature computer numerical control (CNC) capabilities, allowing for complex cutting patterns to be programmed and executed with minimal human intervention. The use of software for nesting and optimizing material use enhances efficiency by reducing waste. Additionally, advancements in sensors and real-time monitoring contribute to quality control, ensuring that each cut meets stringent specifications. With these technological innovations, modern metal cutting lasers are not only precise but also promote sustainability in manufacturing by maximizing resource utilization and minimizing waste.

Comparison of Efficiency Metrics Across Leading Laser Cutting Machines

When evaluating metal cutting laser machines, efficiency metrics play a crucial role in determining their effectiveness in various industrial applications. Speed, precision, and material compatibility are three primary factors that significantly influence a machine’s operational efficiency. Machines that offer a higher cutting speed often improve throughput, allowing manufacturers to complete projects more quickly. Coupled with precision, which ensures clean and accurate cuts, these factors combined enhance overall productivity and reduce waste.

Additionally, energy consumption is an essential metric that impacts both operational costs and environmental sustainability. Machines designed with advanced technology can often deliver better energy efficiency, resulting in lower electricity bills and a smaller carbon footprint. Moreover, the ability to handle diverse materials without compromising on cutting quality is also a vital aspect of efficiency. Laser machines that offer versatility in processing different types of metals are increasingly favored in industries where material choice can vary significantly from project to project. Analyzing these metrics helps manufacturers select the most suitable laser cutting machine for their needs, ensuring optimal performance and cost-effectiveness.

Top 10 Metal Cutting Laser Machines - Efficiency Comparison

Precision Measurement Standards in Metal Laser Cutting Applications

Precision measurement standards are crucial in metal laser cutting applications, as they directly impact the quality, accuracy, and efficiency of the cutting process. In the realm of laser machining, adhering to stringent measurement benchmarks ensures that the final product meets the required specifications. This involves not only the calibration of the laser cutting machines but also the implementation of advanced measurement tools, which can help determine the exact dimensions and tolerances necessary for each job.

To achieve optimal results in metal cutting, operators should prioritize routine maintenance and calibration of their laser machines. Regular checks for alignment, focus, and beam quality can significantly enhance performance and precision. Additionally, incorporating industry-standard measurement techniques, such as laser micrometers or optical comparators, can provide feedback for continuous improvement in cutting quality.

Tips for precision measurement in metal laser cutting:

1. Ensure that your measurement instruments are regularly calibrated to avoid discrepancies.

2. Implement a comprehensive training program for operators to understand the importance of precise measurements.

3. Utilize software that integrates measurement data with the cutting machine for real-time adjustments, enhancing accuracy and efficiency.

Top 10 Metal Cutting Laser Machines for Precision and Efficiency

| Machine Model | Max Cutting Thickness (mm) | Cutting Speed (m/min) | Laser Type | Power (kW) | Precision (mm) |

|---|---|---|---|---|---|

| Model A | 25 | 20 | Fiber Laser | 3 | 0.05 |

| Model B | 20 | 15 | CO2 Laser | 2.5 | 0.1 |

| Model C | 30 | 25 | Fiber Laser | 4 | 0.03 |

| Model D | 22 | 18 | CO2 Laser | 3.5 | 0.07 |

| Model E | 18 | 12 | Fiber Laser | 2 | 0.15 |

| Model F | 35 | 30 | Fiber Laser | 5 | 0.02 |

| Model G | 28 | 22 | CO2 Laser | 4.5 | 0.04 |

| Model H | 24 | 17 | Fiber Laser | 3.2 | 0.1 |

| Model I | 38 | 35 | Fiber Laser | 6 | 0.01 |

| Model J | 32 | 28 | CO2 Laser | 4 | 0.05 |

Market Trends: Growth Projections for the Laser Cutting Industry by 2025

The laser cutting industry is projected to experience significant growth in the coming years, driven by advancements in technology and increasing demand across various sectors. According to a market research report by Global Market Insights, the global laser cutting market is expected to exceed $6 billion by 2025, growing at a compound annual growth rate (CAGR) of over 4%. This growth is primarily fueled by the rising adoption of laser cutting technology in industries such as automotive, aerospace, and manufacturing, where precision and efficiency are critical.

Furthermore, the shift towards automation and smart manufacturing solutions is propelling the demand for metal cutting laser machines. As manufacturers seek to enhance productivity and reduce operational costs, the integration of laser cutting technologies into production lines is becoming increasingly common. A report from Research and Markets highlights that advances in fiber laser technology and increased versatility of laser systems contribute to higher efficiency, allowing for faster processing speeds and improved cutting quality. By 2025, industries are expected to invest more heavily in laser cutting technologies, recognizing their potential to streamline operations and address complex cutting requirements effectively.

Related Posts

-

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing

-

How to Choose the Right Laser Cutting Service for Your Project Needs

-

What is a Sheet Metal Laser Cutting Machine? Benefits and Applications Explained

-

2025 Top 5 Water Jet Cutting Innovations You Need to Know

-

Exploring the Versatility of Metal Tubes: Innovative Applications You Didn't Know About