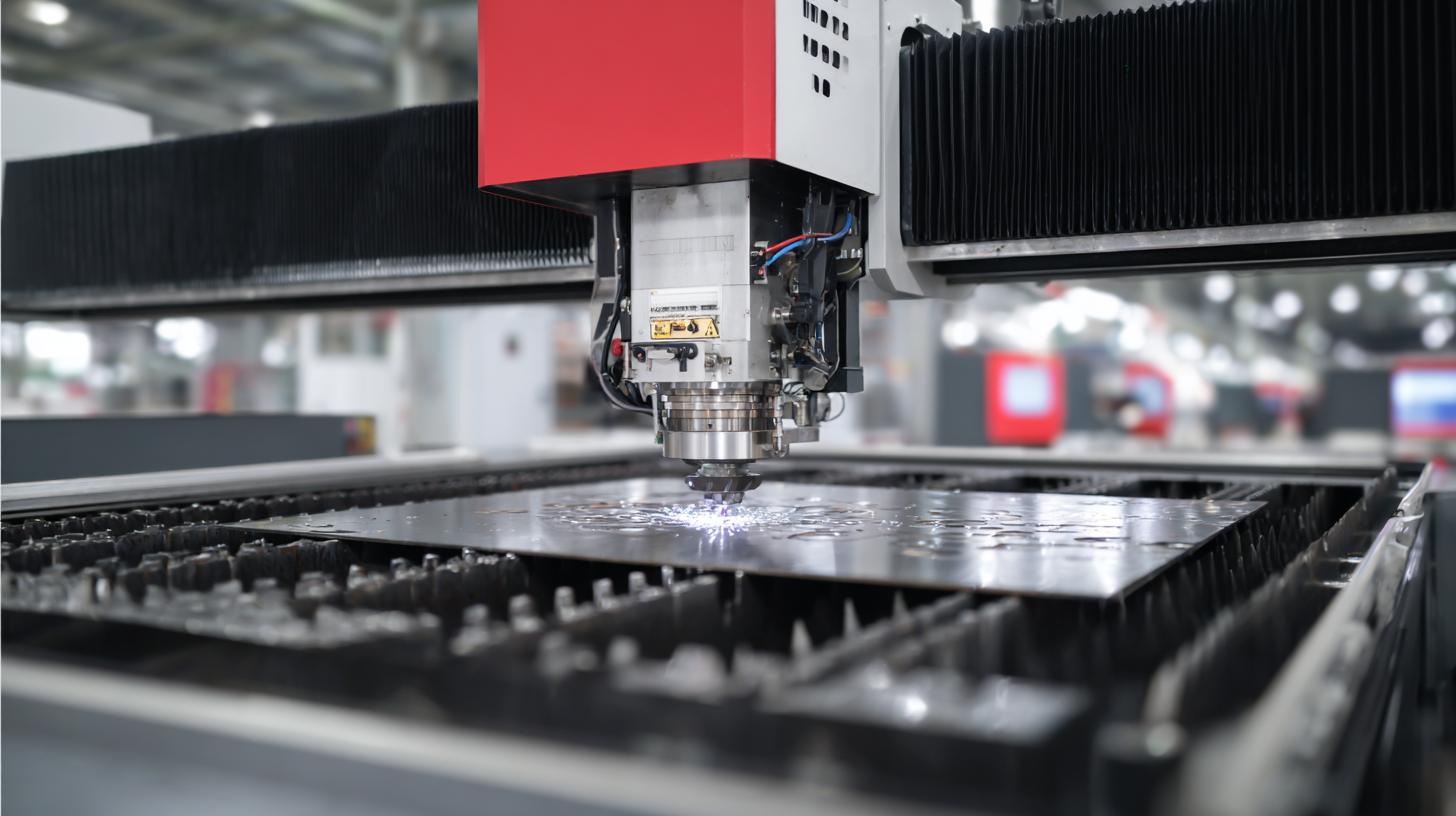

Unlocking Efficiency How Nesting Software Revolutionizes Material Cutting Processes

In today’s fast-paced manufacturing landscape, the integration of technology is pivotal for optimizing processes and enhancing productivity. Nesting software has emerged as a game-changer in the material cutting industry, driving substantial efficiency improvements. According to a report by Technavio, the global nesting software market is projected to grow by over 10% annually, fueled by the increasing need for precision and waste reduction in production processes. This software utilizes advanced algorithms to arrange raw materials into optimal layouts, significantly reducing excess waste and enhancing material usage rates. A case study by the Fabricators & Manufacturers Association indicated that companies utilizing nesting software could reduce material costs by as much as 30%, showcasing its potential to revolutionize traditional cutting methods. Embracing nesting software not only streamlines operations but also aligns with sustainability goals, making it a critical tool for manufacturers aiming to thrive in a competitive environment.

Maximizing Material Utilization: Insights from Current Nesting Software Efficiency Statistics

Nesting software plays a pivotal role in maximizing material utilization, which is increasingly essential in today's competitive manufacturing landscape. By employing advanced algorithms, these programs optimize cutting layouts to minimize waste and enhance efficiency. Recent statistics indicate that modern nesting solutions can significantly lower scrap rates, with some users reporting reductions of up to 30%. This not only leads to cost savings but also contributes to more sustainable production practices, aligning with broader industry goals of waste reduction.

The latest updates in nesting technology, such as automation enhancements and improved user interfaces, are transforming the way fabricators and metal cutters approach their projects. Automated nesting tools streamline part programming and allow for quicker setups, which translates to higher productivity in job shops. As manufacturers seek faster turnaround times and reduced operational costs, the implementation of smart nesting software becomes a crucial differentiator in the marketplace. With AI-driven tools on the rise, the future of material cutting looks set to evolve, offering even greater efficiency and effectiveness in resource management.

Maximizing Material Utilization: Insights from Current Nesting Software Efficiency Statistics

This chart illustrates the efficiency gains in material utilization achieved through the implementation of nesting software in various industries.

The Role of Advanced Algorithms in Reducing Waste and Enhancing Production Outputs

Advanced algorithms are at the heart of nesting software, enabling manufacturers to optimize their material cutting processes significantly. By calculating the most efficient layout for cutting patterns, these algorithms minimize waste and enhance production outputs. According to industry reports, the global market for such technologies is expected to grow steadily, with projections indicating a value of $1.606 billion by 2033, up from $2.181 billion in 2025, marking a compound annual growth rate (CAGR) of 3.9%. This growth reflects the increasing recognition of the importance of efficiency in production environments.

Tips for implementing nesting software effectively include assessing your current cutting processes to identify areas of waste, ensuring that your team is trained to use the software proficiently, and regularly updating the software to leverage new algorithm improvements. Furthermore, integrating this technology with existing systems can streamline operations and provide a comprehensive view of material usage.

Emphasizing the role of data analytics in shaping cutting strategies, businesses are encouraged to adopt a proactive approach. By analyzing material requirements and production patterns, companies can better align their cutting processes with demand, ultimately leading to reduced costs and enhanced profitability.

Case Studies: How Leading Manufacturers Achieve Cost Savings with Nesting Solutions

Nesting software has emerged as a game-changer in the manufacturing sector, particularly in optimizing material cutting processes. Recent case studies reveal that leading manufacturers have reported significant cost savings through the implementation of these solutions. For instance, a study by a leading materials optimization software provider found that companies utilizing nesting strategies can reduce material waste by an impressive 20% to 30%. This reduction not only lowers material costs but also contributes to more sustainable manufacturing practices.

In one exemplary case, a large automotive parts manufacturer integrated nesting software into their production workflow, resulting in a 25% decrease in scrap material. This not only translated to substantial financial savings but also streamlined their production cycle, enabling quicker turnaround times for their products. Additionally, industry reports indicate that companies leveraging advanced nesting solutions see an average improvement of 15% in productivity. As manufacturers increasingly prioritize operational efficiency, nesting software is proving to be an essential tool in their strategic arsenal for cutting costs and enhancing overall performance.

Unlocking Efficiency: How Nesting Software Revolutionizes Material Cutting Processes

| Manufacturing Sector | Material Type | Annual Cost Savings (%) | Production Efficiency Increase (%) | Nesting Software Used |

|---|---|---|---|---|

| Furniture Manufacturing | Plywood | 15% | 25% | CutRite Pro |

| Metal Fabrication | Steel | 20% | 30% | SmartNesting |

| Textile Manufacturing | Cotton | 10% | 20% | Nexcut |

| Construction | Concrete | 12% | 22% | CutMaster 3000 |

| Sign Manufacturing | Acrylic | 18% | 28% | Nesting Genius |

Comparative Analysis: Traditional Cutting Methods vs. Modern Nesting Software Dynamics

In the realm of material cutting, the advent of modern nesting software has presented a paradigm shift away from traditional cutting methods. Traditional approaches often lead to significant material waste, averaging around 20-30% inefficiency, primarily due to suboptimal layouts and human error during the planning stages. In contrast, contemporary nesting software utilizes advanced algorithms to optimize the arrangement of cutting patterns, reducing waste to as little as 5% in some cases. This marked improvement not only contributes to cost savings—provided by reduced raw material needs—but also enhances productivity by streamlining operations.

A comparative analysis of the two methods highlights the operational dynamics at play. Traditional cutting processes heavily rely on manual calculations and labor-intensive setups, which can extend lead times and increase the likelihood of mistakes. A report from the Research and Markets states that businesses utilizing modern nesting software can experience up to a 15% decrease in processing time, thereby expediting production schedules. In addition, this shift towards automation not only minimizes errors but also allows for a more flexible response to market demands, further driving competitiveness in the industry.

Integrating Nesting Software with Industry 4.0: Future Trends and Innovations in Material Cutting Processes

The integration of nesting software with Industry 4.0 is transforming the landscape of material cutting processes. By leveraging advanced technologies such as IoT, artificial intelligence, and big data analytics, nesting software is becoming increasingly sophisticated. These innovations allow manufacturers to optimize their cutting layouts and significantly reduce material waste. Real-time data analysis and machine learning algorithms make it possible to predict demand patterns and adjust production schedules accordingly, ensuring that resources are utilized efficiently.

Moreover, as factories embrace smart manufacturing principles, the synergy between nesting software and robotics is paving the way for unprecedented automation. Automated cutting systems can now communicate directly with nesting software to streamline operations, adjust cuts on-the-fly, and enhance precision. This not only increases throughput but also allows companies to remain agile in a fast-paced market. As these technologies continue to evolve, businesses are poised to revolutionize their production lines, driving cost savings and improving sustainability in the material cutting industry.