Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

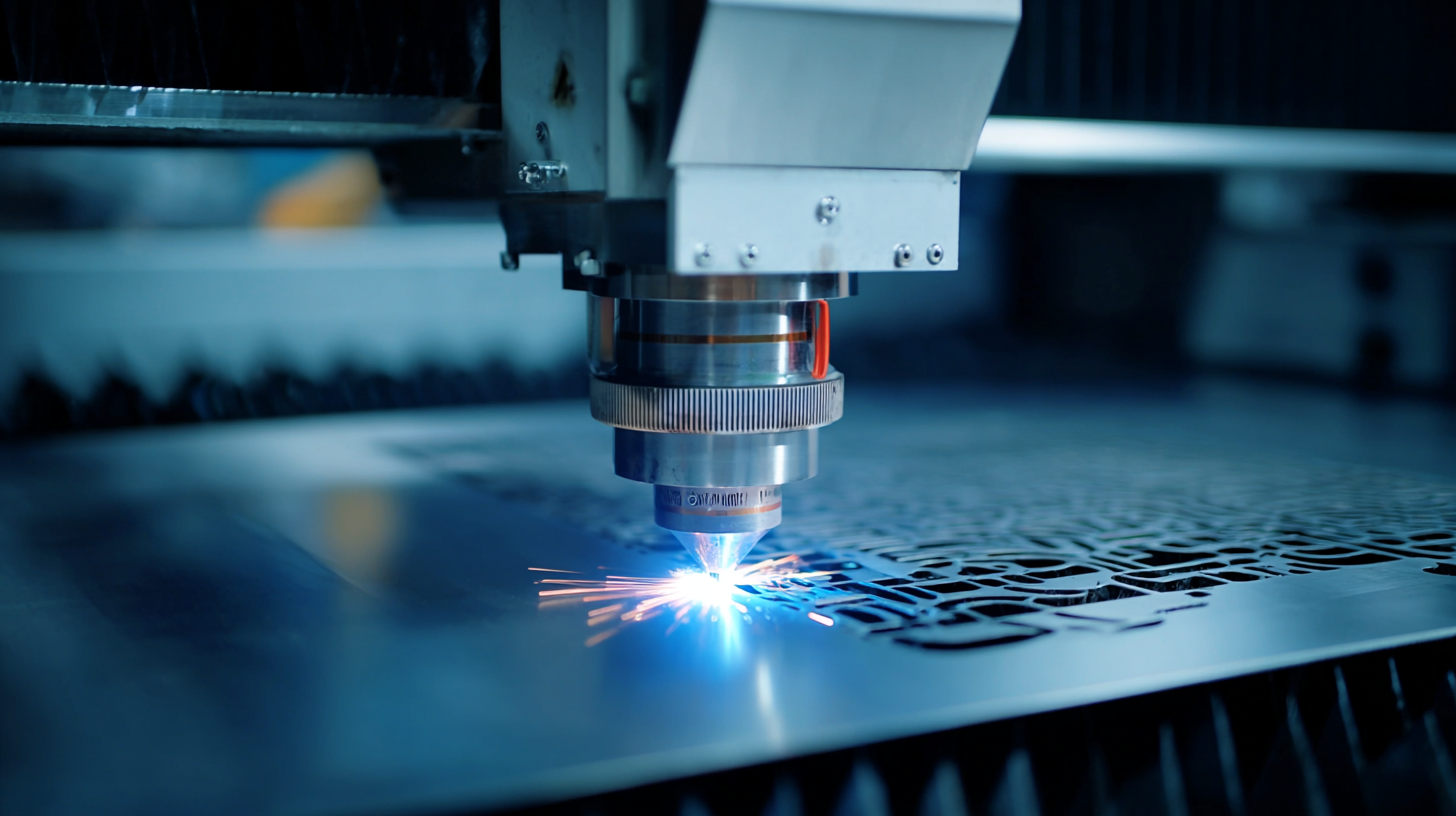

In the rapidly evolving landscape of manufacturing, precision and efficiency are paramount to maintaining a competitive edge. Advanced laser cutting machines have emerged as transformative tools that significantly enhance production capabilities. These state-of-the-art devices leverage cutting-edge technology to deliver impeccable cutting accuracy and speed, allowing manufacturers to tackle complex designs with ease.

In the rapidly evolving landscape of manufacturing, precision and efficiency are paramount to maintaining a competitive edge. Advanced laser cutting machines have emerged as transformative tools that significantly enhance production capabilities. These state-of-the-art devices leverage cutting-edge technology to deliver impeccable cutting accuracy and speed, allowing manufacturers to tackle complex designs with ease.

With the ability to cut through various materials, from metals to plastics, laser cutting machines are versatile solutions that optimize workflows and minimize waste. As industries increasingly adopt digitalization, integrating these machines into manufacturing processes not only boosts operational efficiency but also facilitates innovation. Embracing the power of laser cutting technology is essential for manufacturers aiming to unlock new levels of productivity and precision in their operations.

Advantages of Laser Cutting Technology in Precision Manufacturing

The integration of laser cutting technology in precision manufacturing offers a myriad of advantages that significantly enhance production efficiency and product quality. One of the foremost benefits is the remarkable accuracy that laser machines provide, enabling the creation of intricate designs and tight tolerances that would be difficult, if not impossible, to achieve with traditional cutting methods. This high level of precision minimizes material waste and reduces the need for extensive post-processing, ultimately streamlining the manufacturing workflow.

The integration of laser cutting technology in precision manufacturing offers a myriad of advantages that significantly enhance production efficiency and product quality. One of the foremost benefits is the remarkable accuracy that laser machines provide, enabling the creation of intricate designs and tight tolerances that would be difficult, if not impossible, to achieve with traditional cutting methods. This high level of precision minimizes material waste and reduces the need for extensive post-processing, ultimately streamlining the manufacturing workflow.

Moreover, laser cutting machines boast exceptional versatility across a range of materials, from metals to plastics and composites. This adaptability allows manufacturers to use laser cutting for diverse applications, including automotive parts, aerospace components, and ornamental designs. The ability to easily switch between different materials and thicknesses without major adjustments enhances operational flexibility, making it easier to respond to evolving market demands. As a result, companies can maximize productivity while maintaining the high standards of quality that consumers expect.

Impact of Laser Cutting Machines on Production Efficiency and Cost Reduction

The laser cutting machine market has witnessed significant growth, driven by advancements in technology and increasing demand for precision manufacturing. Recent reports indicate that the global market size for laser cutting machines is projected to reach approximately $6.5 billion by 2026, with a compound annual growth rate (CAGR) of around 5.8% from 2021 to 2026. The rising adoption of fiber laser technology, which is known for its efficiency and lower operational costs, is expected to dominate the market, especially in automotive and aerospace applications.

The impact of laser cutting machines on production efficiency cannot be overstated, particularly as manufacturers seek to reduce costs and improve output quality. With the ability to deliver precise cuts at high speeds, laser cutting technology has become crucial in streamlining manufacturing processes. Moreover, the COVID-19 pandemic has accelerated the shift towards automation, resulting in an increased demand for automated and robotic laser cutting systems. As companies adapt to new technological solutions in the post-pandemic landscape, the trend towards greater production efficiency and cost reduction through advanced laser cutting machines continues to gain momentum.

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

| Parameter | Value |

|---|---|

| Cutting Speed (m/min) | 50 - 300 |

| Accuracy (mm) | ± 0.05 |

| Material Thickness (mm) | 0.5 - 25 |

| Operational Cost Reduction (%) | 20 - 50 |

| Increase in Productivity (%) | 30 - 70 |

| Setup Time (minutes) | 5 - 10 |

| Waste Material Reduction (%) | 15 - 40 |

Key Technical Innovations Driving Advanced Laser Cutting Solutions

In the realm of advanced laser cutting machines, significant technical innovations are transforming manufacturing efficiency and precision. A recent market analysis reveals that the global laser technology market is projected to grow from USD 18.2 billion in 2024 to USD 31.4 billion by 2033, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth is largely driven by the rising adoption of high-performance laser technologies across various industries, including textiles and automotive, where precision cutting is paramount.

Key advancements in fiber laser technology are further propelling this industry forward. Fiber lasers offer improved energy efficiency and cutting speed, which are critical for high-volume production environments. With the expectation that the fiber laser market will reach USD 12.8 billion, growing at a CAGR of 11.5% from 2025 to 2035, manufacturers are increasingly integrating these systems to enhance operational capabilities. Moreover, the shift towards automation and smart manufacturing practices underscores the necessity for cutting-edge laser solutions that can meet the demands of modern production workflows. As manufacturers continue to innovate and invest, the role of advanced laser cutting technologies will be pivotal in achieving both precision and efficiency in the manufacturing landscape.

Industry Trends: The Growing Market Demand for Laser Cutting Machinery

The laser cutting machinery market is experiencing significant growth, driven by increasing demands for precision and efficiency across various manufacturing applications. According to recent industry reports, the laser processing market is projected to climb from USD 26.56 billion in 2025 to an impressive USD 42.73 billion by 2030. This rapid expansion underscores the rising reliance on advanced laser technologies within the broader metal fabrication equipment sector.

In addition to this growth, the laser cutting machines market alone is anticipated to expand at a CAGR of 6.5% from 2025 to 2034, potentially reaching a value of around USD 7.3 billion by the end of the forecast period. This reflects a broader trend where precision engineering and automation are increasingly essential for manufacturers aiming to optimize their production processes. Coupled with the overall metal cutting tools market, expected to surge from USD 80.87 billion in 2023 to USD 113.04 billion by 2030, the data illustrates a compelling narrative of innovation and opportunity within the manufacturing landscape.

Comparative Analysis of Laser Cutting vs. Traditional Manufacturing Methods

The comparative analysis of laser cutting and traditional manufacturing methods reveals significant differences in precision and efficiency. Traditional methods often rely on mechanical cutting tools that can lead to material waste and variations in the finished product. These conventional techniques tend to operate at slower speeds, making it challenging to meet the growing demands of modern manufacturing.

In contrast, advanced laser cutting machines offer a non-contact cutting solution that can achieve intricate designs with minimal waste. The focused laser beam allows for finer tolerances, resulting in high-quality finishes that meet stringent specifications.

In contrast, advanced laser cutting machines offer a non-contact cutting solution that can achieve intricate designs with minimal waste. The focused laser beam allows for finer tolerances, resulting in high-quality finishes that meet stringent specifications.

Moreover, the efficiency of laser cutting extends beyond just speed and precision. The automation and programmability of laser cutting machines enable manufacturers to streamline their operations and reduce setup times. This adaptability makes it easier to switch between different materials and designs without significant downtime, further enhancing productivity. As industries seek to optimize their processes and reduce costs, laser cutting emerges as a superior alternative to traditional manufacturing, paving the way for innovation and enhanced competitiveness in the market.