What is a Sheet Metal Laser Cutting Machine? Benefits and Applications Explained

The sheet metal laser cutting machine represents a significant advancement in manufacturing technology, offering precision and efficiency that traditional cutting methods often cannot match. According to a recent industry report from MarketsandMarkets, the global laser cutting machine market is expected to reach USD 5.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5% from 2020. This growth is driven by the increasing demand for automation in manufacturing processes and the rise in demand for customized products across various sectors.

John Smith, a leading expert in laser technology and author of “Innovations in Laser Cutting,” emphasizes the transformative power of these machines, stating, "The adoption of sheet metal laser cutting machines not only enhances product quality but also optimizes production time, making it a game-changer for businesses aiming to stay competitive."

As industries continue to evolve, the application of sheet metal laser cutting machines spans a wide range of sectors including automotive, aerospace, and electronics, proving to be an invaluable asset for enhancing productivity and minimizing waste. Understanding the capabilities and advantages of these machines is crucial for businesses looking to innovate and improve their manufacturing capabilities.

Understanding Sheet Metal Laser Cutting Machines

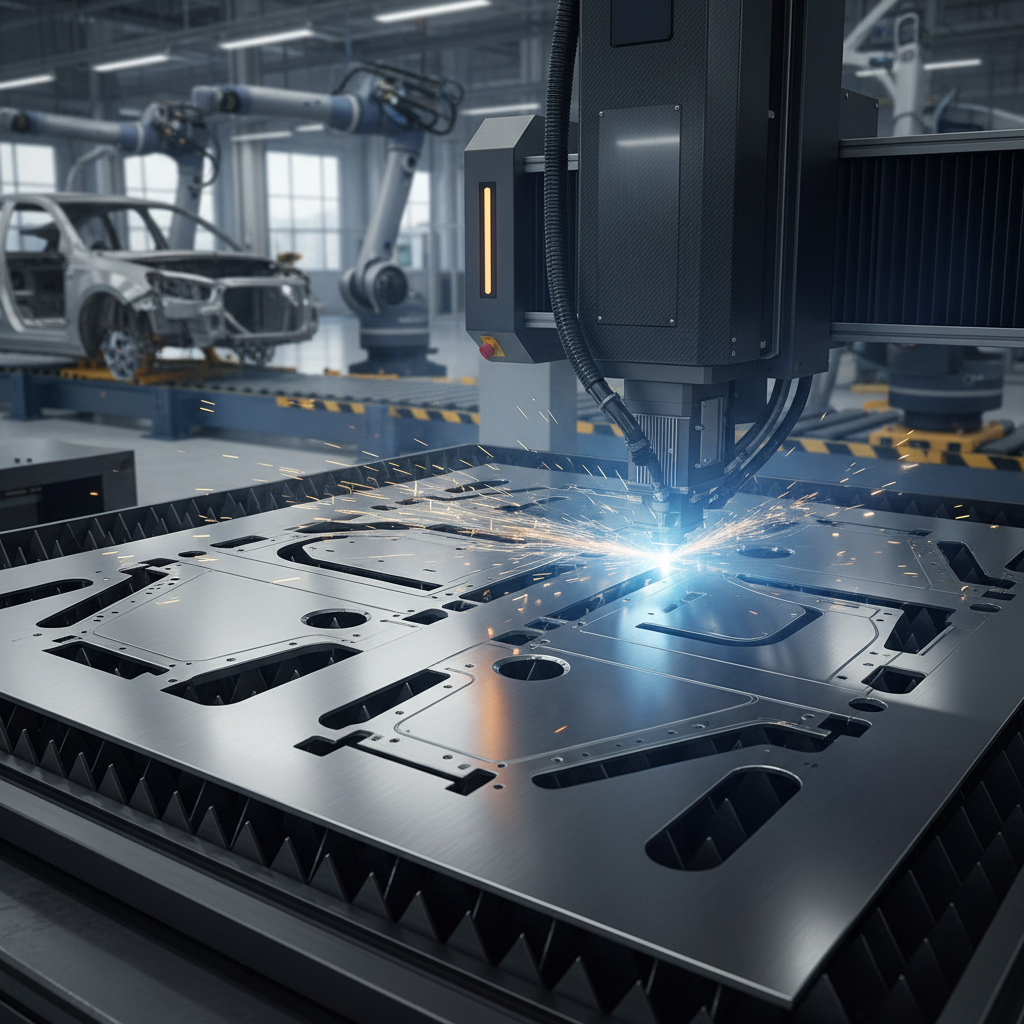

Sheet metal laser cutting machines are advanced tools that utilize high-powered lasers to cut and shape metal sheets with remarkable precision. These machines operate by directing a laser beam onto the material, melting away the metal along designated paths. This technology has gained significant traction in various industries due to its ability to produce intricate designs and maintain tight tolerances. According to a report by MarketsandMarkets, the global sheet metal fabrication market is anticipated to grow from $240.03 billion in 2021 to $319.26 billion by 2026, with laser cutting playing a crucial role in this expansion.

Understanding the components and functionalities of sheet metal laser cutting machines is essential for manufacturers looking to enhance productivity and efficiency. These machines typically feature an automated system that allows for rapid setup and operation, significantly reducing production times compared to traditional cutting methods. The application of laser cutting technology is vast, spanning automotive, aerospace, and electronics sectors, where precision is paramount. A study from Grand View Research highlighted that the metal cutting machines market is expected to reach $5.5 billion by 2025, further indicating the growing reliance on laser cutting for complex sheet metal applications.

Key Benefits of Using Laser Cutting Technology in Manufacturing

Laser cutting technology has revolutionized the manufacturing landscape by offering a range of key benefits that enhance efficiency, precision, and cost-effectiveness. One of the most significant advantages is its ability to deliver high levels of accuracy and intricate detail in various materials, including metals, plastics, and composites. The focused laser beam allows for clean cuts with minimal material wastage, reducing production costs while maintaining high quality standards.

Moreover, the versatility of laser cutting machines makes them suitable for a variety of applications across different industries, from automotive to electronics and renewable energy. These machines can easily adapt to different production requirements, enabling manufacturers to respond quickly to market demands and innovate their product lines. By integrating advanced laser cutting technology, companies can not only increase their operational efficiency but also enhance their competitive edge in an ever-evolving marketplace. As the demand for precision and automation in manufacturing continues to grow, the role of laser cutting in streamlining processes and improving output will only become more pronounced.

Applications of Laser Cutting in Various Industries

Laser cutting technology has revolutionized various industries by providing precise and efficient cutting solutions. In the automotive sector, laser cutting machines are used for creating intricate components, ensuring high accuracy and repeatability. This precision is crucial for manufacturing parts that must fit perfectly in the assembly line, reducing waste and improving overall production efficiency.

In the aerospace industry, the lightweight characteristics of sheet metal make laser cutting an optimal choice for fabricating complex shapes and parts with high strength-to-weight ratios. The ability to cut through materials like aluminum and titanium with minimal thermal distortion is essential for maintaining the structural integrity of aircraft components. Additionally, the medical field utilizes laser cutting for producing custom surgical tools and devices, where hygiene and precision are paramount, thus enhancing patient safety and operational efficiency.

Furthermore, the construction industry benefits from laser cutting for creating intricate designs in metal facades and structural elements, allowing for greater aesthetic appeal while maintaining robustness. With applications spanning these diverse fields, laser cutting continues to drive innovation and efficiency across the board.

Comparison of Laser Cutting with Traditional Cutting Methods

Laser cutting technology has revolutionized the way sheet metal is processed, offering several advantages over traditional cutting methods such as plasma or mechanical cutting. One of the most significant differences lies in precision. Laser cutting provides extremely fine and accurate cuts, reducing the need for extensive finishing work. This precision is particularly beneficial for complex designs and intricate patterns, which often pose challenges for conventional cutting techniques.

Another key advantage of laser cutting is the reduced heat-affected zone (HAZ). Traditional methods often produce a larger HAZ due to the high temperatures involved, which can lead to warping or changes in the material properties. In contrast, laser cutting minimizes these risks, ensuring high-quality edges and maintaining the structural integrity of the metal. Additionally, laser cutting can operate at higher speeds and with lower operational costs compared to traditional methods, making it a more efficient option for manufacturers seeking to optimize their production processes.

Future Trends in Sheet Metal Laser Cutting Technology

Sheet metal laser cutting technology is rapidly evolving, driven by the need for high precision and efficiency in manufacturing. As highlighted in recent studies, the global market for metal processing equipment is projected to grow significantly, reaching an estimated value of $617.8 billion by 2032, with a compound annual growth rate of 8.20% from 2025. Laser cutting is increasingly favored for its ability to replace traditional methods, offering enhanced speed and quality, which is reflected in the sector’s growth momentum.

The trend towards customization and smaller production runs is reshaping the laser cutting landscape. Many companies are shifting from mass production to meeting specific, individual customer demands, presenting a lucrative opportunity for laser technology. As reported, China's laser processing equipment market size is expected to reach approximately $89.9 billion by 2024, driven by ongoing domestic innovations and an increasing emphasis on high-tech solutions in manufacturing.

**Tip 1:** When considering laser cutting systems, prioritize equipment that offers flexibility in handling diverse materials and thicknesses.

**Tip 2:** Stay updated on advancements in laser technology, as they can significantly improve production efficiency and reduce material waste.

**Tip 3:** Explore partnerships with local suppliers capable of providing tailored services, as this can enhance your competitive edge in the growing market.

Sheet Metal Laser Cutting Technology: Benefits and Applications

Related Posts

-

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing

-

2025 Top 5 Water Jet Cutting Innovations You Need to Know

-

How to Choose the Right Laser Cutting Service for Your Project Needs

-

Unlocking Efficiency How Nesting Software Revolutionizes Material Cutting Processes

-

Exploring Advanced Metal Welding Techniques: Boosting Efficiency and Quality in Industrial Applications