Top 10 Sheet Metal Cutting Machines You Should Know About?

In the world of manufacturing, knowledge is power, especially when it comes to the choice of tools. The sheet metal cutting machine is crucial for fabrication projects. Isaiah Moore, an industry expert, once said, "Choosing the right sheet metal cutting machine can make or break your production efficiency." His insight highlights the need for informed decisions.

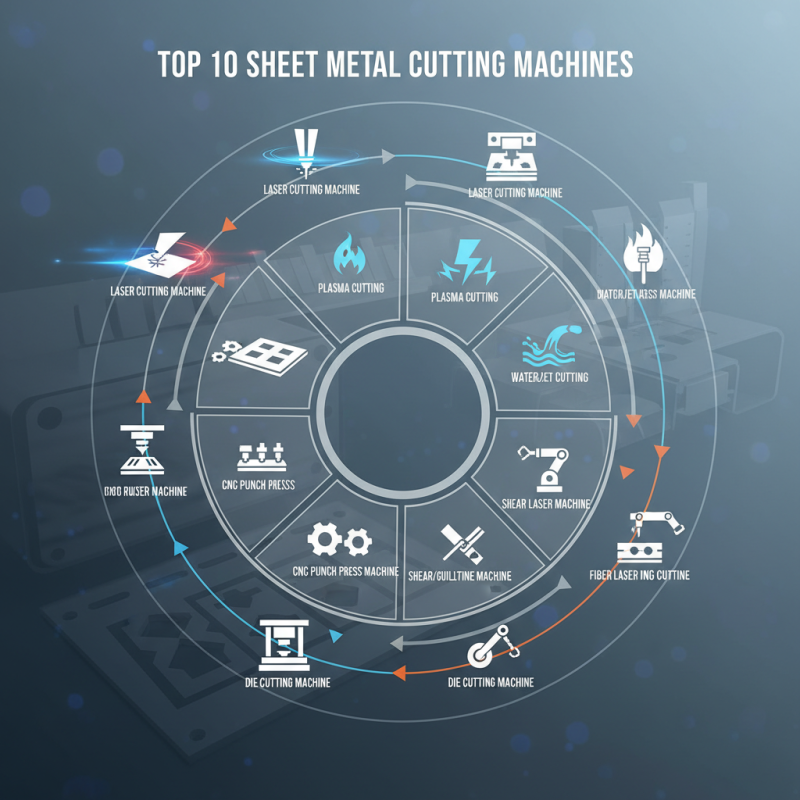

Understanding the various types of sheet metal cutting machines is essential. These machines vary in technology and efficiency. Some utilize lasers, while others use plasma or water jet cutting. Each method has unique advantages but also limitations. Quality and precision remain priorities in any project, yet many still struggle with selecting the ideal machine.

Navigating through the myriad options can be overwhelming. Manufacturers may feel uncertain about which machine fits their specific needs. This confusion can lead to frustration and costly mistakes. Meanwhile, the competition demands constant adaptation to new technologies. Thus, exploring the top 10 sheet metal cutting machines is not just beneficial; it's necessary for success.

Overview of Sheet Metal Cutting Machines

Sheet metal cutting machines are vital in many industries. They bring precision and efficiency to the manufacturing process. Understanding their types helps in making a wise choice for your projects. There are various models available, each with unique features. Some are designed for small workshops, while others cater to large-scale production.

These machines can operate using different methods. For instance, laser cutting offers high accuracy. Plasma cutting, on the other hand, is faster for thicker materials. However, efficiency can vary based on the type of metal and thickness. Not all machines perform well under specific conditions. It's crucial to consider the intended application when selecting a machine.

Maintenance is another critical factor. Regular checks can prevent downtime and costly repairs. Many users tend to overlook this aspect. Neglecting it can lead to performance issues. Additionally, some machines have a steeper learning curve. Training is essential to maximize their potential. Without proper understanding, mistakes can happen.

Types of Sheet Metal Cutting Techniques

When considering sheet metal cutting techniques, several options stand out. Each method has unique advantages and drawbacks. Laser cutting uses a focused beam to slice through metal. It delivers precise cuts but requires careful calibration. This can be challenging for beginners.

Plasma cutting is another popular technique. It employs a high-velocity jet of ionized gas. This method is speedy and effective for thicker materials. However, it may leave rough edges that require additional finishing. Many users find the learning curve steep.

Waterjet cutting is a versatile option as well. It uses high-pressure water mixed with abrasives to cut through metals. This method is excellent for intricate designs, yet it can be slower than others. The cost of machinery and maintenance can also be a concern. Exploring these options helps determine the most suitable method for your needs.

Top 10 Sheet Metal Cutting Machines: Comparison of Different Techniques

Key Features to Consider When Choosing a Machine

When choosing a sheet metal cutting machine, several key features come into play. The cutting capacity is crucial. It indicates how thick and wide the material the machine can handle. Machines vary widely. Some cut thin sheets easily, while others are designed for heavy-duty tasks. Pay attention to the gauge rating. This will help you understand what materials you can work with.

Another feature to consider is the cutting speed. Faster is not always better. A speedy machine may sacrifice precision. You want a balance between speed and accuracy. Look for machines with adjustable speeds. This allows better control on different materials. Additionally, the type of cutting technology matters. Plasma, laser, and waterjet all have unique advantages. Choosing the right one depends on your specific needs.

Don’t overlook ease of use. A complicated interface could hinder productivity. Machines should have intuitive controls. Training staff on complex operations is time-consuming. Maintenance requirements are also critical. Some machines need regular checks. Others demand little oversight. Understanding these aspects can help avoid costly downtimes. Reflecting on these features leads to smarter choices in the long run.

Top 10 Sheet Metal Cutting Machines You Should Know About

| Machine Model | Cutting Method | Max Sheet Thickness | Sheet Size Capacity | Power Consumption | Weight |

|---|---|---|---|---|---|

| Model A | Laser Cutting | 20 mm | 1500 x 3000 mm | 10 kW | 2000 kg |

| Model B | Plasma Cutting | 35 mm | 2000 x 4000 mm | 15 kW | 1200 kg |

| Model C | Waterjet Cutting | 150 mm | 3000 x 6000 mm | 30 kW | 3500 kg |

| Model D | Oxy-Fuel Cutting | 50 mm | 4000 x 8000 mm | 8 kW | 3000 kg |

| Model E | Electro-Hydraulic | 15 mm | 1000 x 2000 mm | 12 kW | 1100 kg |

| Model F | Fiber Laser Cutting | 20 mm | 1500 x 3000 mm | 12 kW | 1800 kg |

| Model G | Die Cutting | 12 mm | 1000 x 1000 mm | 5 kW | 800 kg |

| Model H | CNC Shearing | 25 mm | 1500 x 3000 mm | 7 kW | 1200 kg |

| Model I | Laser Engraving | 5 mm | 500 x 1000 mm | 6 kW | 600 kg |

| Model J | Ultrasonic Cutting | 10 mm | 1200 x 2500 mm | 9 kW | 950 kg |

Top 10 Sheet Metal Cutting Machines in the Market

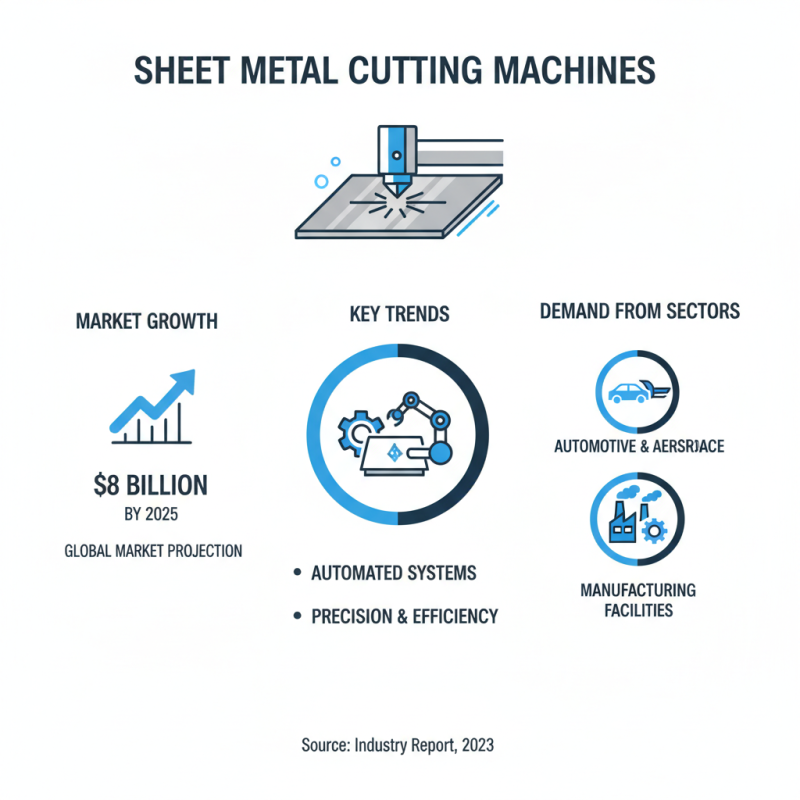

When it comes to sheet metal cutting machines, several options stand out in the market today. According to a recent industry report, the global sheet metal cutting machine market is poised to reach $8 billion by 2025. This growth reflects the increasing demand from various sectors such as automotive and aerospace. Many manufacturing facilities are considering automated systems for precision and efficiency.

Laser cutting machines are often preferred for their accuracy. They can handle complex designs with minimal waste. Waterjet machines also offer unique advantages, particularly for thicker materials. However, they typically require more maintenance. For those working with lighter metals, plasma cutting machines remain popular. Yet, they may not deliver the same level of precision.

Despite the advantages, operators must be mindful of the potential downsides. The initial investment can be substantial. Additionally, the learning curve for advanced machines can be steep. It’s important to assess the specific needs of the manufacturing process before making a decision. Poor choices can lead to increased downtime and lost production. Understanding the capabilities and limitations of each machine is critical for optimizing performance.

Maintenance Tips for Sheet Metal Cutting Machines

Maintenance is crucial for sheet metal cutting machines. Regular upkeep can extend equipment life and improve performance. According to industry reports, well-maintained machines can increase efficiency by up to 30%. Simple tasks like cleaning and lubrication can make a significant difference. Neglecting these tasks can lead to costly repairs and downtime.

Routine inspections are essential. Check for wear and tear regularly. Look for signs of rust or damage to cutting edges. A worn blade can create poor cuts and reduce quality. In fact, 40% of machine failures come from improper maintenance. It's vital to address small issues before they escalate. Keep a maintenance log to track services and repairs. This information can help in predicting future needs and improving operational efficiency.

Operators should receive training on proper handling. This can minimize errors and accidents. Misuse can lead to safety hazards and equipment failure. Investing in operator education pays off. A study highlighted that companies with trained staff see 20% fewer machine-related accidents. Proper maintenance and operator training can significantly enhance machine longevity and performance.

Related Posts

-

Top Benefits of Using a Laser Cutting Machine for Your Projects

-

Top 10 Best Metal Tubes for Your DIY Projects in 2023

-

Why Choose a Metal Cutting Laser Machine for Your Manufacturing Needs?

-

2025 Top 5 Water Jet Cutting Innovations You Need to Know

-

Exploring the Impact of Robotic Welding Technology on Manufacturing Efficiency and Quality Metrics

-

How to Choose the Right Industrial Sheet Metal for Your Project Needs