2025 Top 10 Water Jet Cutting Machines for Precision and Efficiency

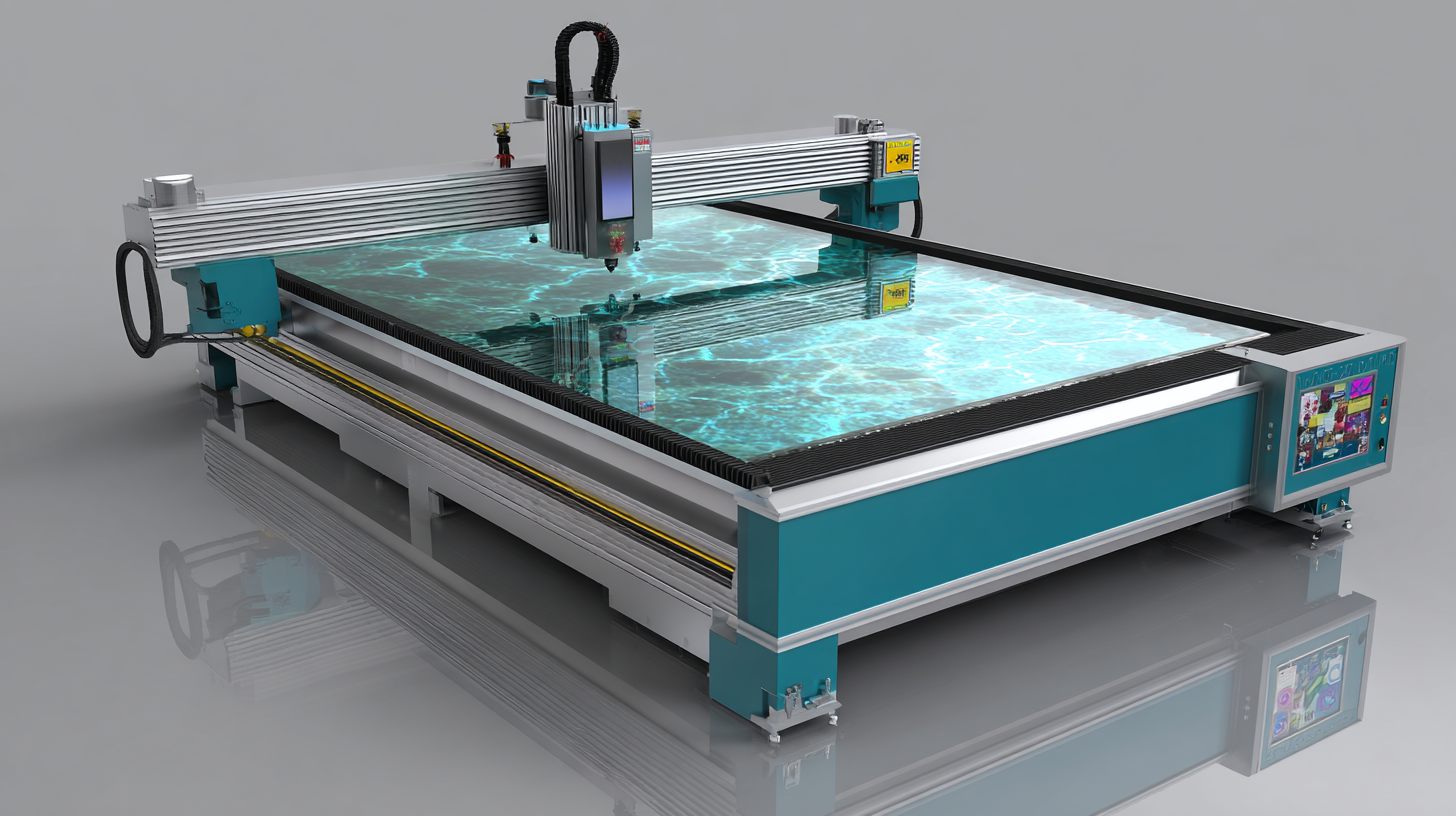

The water jet cutting machine has revolutionized the manufacturing landscape by offering precision and efficiency that traditional cutting methods cannot match. According to a report by Markets and Markets, the global water jet cutting machine market is expected to reach USD 1.36 billion by 2025, growing at a CAGR of 6.4% from 2020 to 2025. This rise is primarily driven by increasing demand for high-precision cutting processes in industries such as aerospace, automotive, and metal fabrication, where tolerances need to be tight and waste needs to be minimized.

Water jet cutting machines utilize a high-pressure stream of water, often in combination with abrasives, to cut through various materials with unparalleled accuracy. This technology not only reduces production waste but also allows for the cutting of complex shapes and materials that are challenging to machine through conventional means. As industries strive for greater efficiency and lower production costs, the adoption of water jet cutting machines is expected to surge, making it a focal point in manufacturing advancements and competitive strategies. With the ongoing evolution of this technology, understanding the top machines available in 2025 will empower businesses to remain at the forefront of precision engineering.

Top Features to Look for in Water Jet Cutting Machines for 2025

When selecting a water jet cutting machine for 2025, several key features should be prioritized to ensure both precision and efficiency. First and foremost, advanced control systems play a crucial role in achieving high accuracy in cutting applications. Machines equipped with state-of-the-art software for motion control allow for complex shapes and fine details to be executed with minimal deviation. The ability to fine-tune parameters such as pressure and speed based on material type further enhances the precision of cuts.

In addition to control systems, the versatility of the water jet cutting machine is another critical aspect. Models that support multiple cutting techniques, including abrasive and pure water jet cutting, offer users greater flexibility in handling various materials, from metals to glass and composites. Additionally, the machine’s compatibility with automated loading and unloading systems can significantly boost operational efficiency, reducing downtime and labor costs. As manufacturers strive to stay competitive, these features will define the most effective water jet cutting solutions for the ever-evolving industrial landscape in 2025.

Innovative Technologies Enhancing Precision in Water Jet Cutting

The rapid advancements in technology are profoundly shaping the capabilities of water jet cutting machines, enhancing their precision and efficiency. Among the most innovative technologies are advanced control systems that utilize artificial intelligence and machine learning algorithms. These systems analyze cutting parameters in real time, allowing for instantaneous adjustments that optimize the cutting process. This results in cleaner edges and reduced material waste, pushing the boundaries of what water jet cutting can achieve across various industries.

Additionally, improvements in nozzle design and high-pressure pump technology are driving enhanced performance. Modern water jet cutting machines feature ultra-high pressure capabilities that increase the speed and quality of cuts, enabling operators to work with a wider range of materials, including tough composites and metals. Coupled with advanced motion control, these technologies are enhancing operational efficiency, reducing downtime, and allowing for intricate designs that were previously unattainable. As these innovations continue to evolve, they are setting new industry standards for cutting precision and operational excellence.

2025 Top 10 Water Jet Cutting Machines for Precision and Efficiency

| Model | Max Cutting Pressure (psi) | Table Size (inches) | Accuracy (inches) | Water Consumption (gallons/hour) | Weight (lbs) | Features |

|---|---|---|---|---|---|---|

| Model A | 60,000 | 60x120 | ±0.005 | 5 | 1,500 | Integrated control system, multi-axis cutting |

| Model B | 80,000 | 80x160 | ±0.003 | 7 | 2,200 | Advanced motion control, high-speed operation |

| Model C | 55,000 | 48x96 | ±0.004 | 4 | 1,200 | Compact design, user-friendly interface |

| Model D | 75,000 | 72x144 | ±0.002 | 6 | 2,000 | High precision, energy efficient |

| Model E | 65,000 | 60x120 | ±0.005 | 5 | 1,600 | User-friendly controls, customizable options |

| Model F | 70,000 | 84x168 | ±0.003 | 6 | 2,500 | Robust structure, ideal for heavy materials |

| Model G | 60,000 | 48x96 | ±0.006 | 4 | 1,000 | Easy maintenance, portable option |

| Model H | 75,000 | 72x144 | ±0.002 | 5 | 2,100 | Robust software integration, multi-material cutting |

| Model I | 80,000 | 80x160 | ±0.003 | 8 | 2,300 | High speed, precision calibration |

| Model J | 65,000 | 60x120 | ±0.005 | 5 | 1,800 | Efficient pumping system, low vibration |

Comparative Review of the Leading Water Jet Cutting Machines

In the realm of manufacturing and fabrication, water jet cutting machines have gained prominence for their precision and efficiency. This comparative review highlights the leading models of 2025, focusing on their unique features and performance metrics. These machines utilize high-pressure water mixed with abrasive materials to cut through various materials with minimal kerf, making them ideal for intricate designs and hard substrates. Key players in the industry are noted for their innovative technologies that enhance both speed and accuracy, catering to diverse industrial needs.

Tips for selecting the right water jet cutting machine include considering the size of the job and the type of materials typically processed. Evaluate the machine's cutting speed and the maximum thickness it can handle to ensure it aligns with production requirements. Additionally, focus on the manufacturer's customer support and the availability of spare parts, as these factors are crucial for long-term operational efficiency.

When implementing a water jet cutting machine, regular maintenance checks are essential to sustain precision and prolong the equipment's lifespan. Keeping the nozzle and pump system clean can prevent wear and enhance cutting performance. Furthermore, investing in software that optimizes cutting paths can significantly improve overall workflow and reduce material waste, leading to cost savings in the long run.

2025 Top 10 Water Jet Cutting Machines for Precision and Efficiency

This chart compares the cutting speed and precision rating of the top 10 water jet cutting machines of 2025. The data illustrates how each machine performs in these critical areas, highlighting their efficiency and effectiveness in cutting various materials.

Efficiency Boosting Tips for Optimizing Water Jet Cutting Performance

In the realm of water jet cutting, optimizing performance is crucial for achieving precision and efficiency. One effective method is to leverage advancements in technology, such as the incorporation of artificial intelligence and machine learning. These tools can predict Material Removal Rates (MRR) in Abrasive Water Suspension Jet (AWSJ) machining, facilitating better decision-making and enhancing overall productivity when working with complex materials like CFRP composites.

Additionally, upgrading equipment can lead to significant improvements in cutting efficiency. For instance, cutting systems equipped with advanced pump technologies deliver up to 30% more horsepower to the cutting nozzle, ensuring a cleaner and faster cut. Implementing best practices, such as regular maintenance and appropriate pressure settings, further maximizes the capabilities of water jet systems. By focusing on these efficiency-boosting tips, operators can not only enhance the performance of their water jet cutters but also expand their operational capabilities, leading to greater success in various industries.

Cost Considerations: Budgeting for the Best Water Jet Cutting Machines

When investing in a water jet cutting machine, cost considerations are paramount for any business aiming for precision and efficiency. The initial price of the machine is just one aspect; companies must also factor in additional expenses such as maintenance, replacement parts, and operating materials. It's crucial to establish a comprehensive budget that encompasses both upfront costs and ongoing operational expenses.

Moreover, the return on investment (ROI) should be evaluated through the lens of productivity gains and reduced material waste. Selecting a cutting machine that not only fits the budget but also meets production demands can lead to significant savings in the long run. Businesses should weigh the cost against features like cutting speed, precision, and durability, ensuring they choose a machine that aligns with their specific needs and maximizes their operational efficiency.

Related Posts

-

Exploring the Versatility of Metal Tubes: Innovative Applications You Didn't Know About

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing

-

Unlocking Efficiency How Nesting Software Revolutionizes Material Cutting Processes

-

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

-

Exploring Advanced Metal Welding Techniques: Boosting Efficiency and Quality in Industrial Applications

-

Exploring the Impact of Robotic Welding Technology on Manufacturing Efficiency and Quality Metrics