2025 Top 5 Industrial Equipment Trends Transforming the Manufacturing Sector

In the ever-evolving landscape of the manufacturing sector, the significance of industrial equipment cannot be overstated. According to a recent report by McKinsey & Company, the Industrial IoT (IIoT) could unlock up to $4 trillion in value across industries, emphasizing the need for manufacturers to adopt cutting-edge technology to enhance efficiency and productivity. As we approach 2025, the integration of advanced industrial equipment is set to reshape traditional processes, streamline operations, and drive competitive advantage.

The rise of automation, robotics, and smart manufacturing technologies indicates a profound transformation. A study by the World Economic Forum suggests that by 2025, more than 85 million jobs may be displaced by a shift in labor between humans and machines, while 97 million new roles could emerge, reflecting the critical role of smart industrial equipment in this transition. As businesses navigate these changes, understanding the top trends influencing industrial equipment will be essential for staying ahead in a competitive market.

This article will explore the top five trends destined to redefine the industrial equipment landscape in 2025, highlighting key insights that will empower manufacturers to innovate and thrive in an increasingly complex environment. By examining these trends, industry stakeholders can better prepare for the technological advancements that will drive the future of manufacturing.

Emergence of Smart Manufacturing Technologies and Their Impact on Productivity

The emergence of smart manufacturing technologies is significantly transforming the manufacturing sector, enhancing productivity and operational efficiency. The integration of artificial intelligence (AI) into manufacturing processes has enabled companies to achieve substantial improvements in green total factor productivity (GTFP). This shift not only supports China's transition to a more sustainable development model but also lays the foundation for long-term economic growth by optimizing resource use and minimizing waste.

Innovative tools such as digital twin technology and generative AI are further revolutionizing manufacturing practices. Digital twins facilitate real-time monitoring of production processes, which helps maintain high-quality standards and enhances decision-making. Meanwhile, generative AI drives creativity in design and production, enabling manufacturers to develop customized solutions that meet market demands more effectively. As smart factories become more prevalent, the focus remains on leveraging technology to improve agility, attract top talent, and foster a culture of continuous improvement, ultimately leading to increased productivity across the manufacturing landscape.

Impact of Smart Manufacturing Technologies on Productivity (2025)

The Rise of AI and Machine Learning in Industrial Equipment Optimization

The integration of artificial intelligence (AI) and digital twin technology is poised to revolutionize the manufacturing sector by enhancing industrial equipment optimization. By leveraging advanced simulation designs and high-resolution modeling, AI facilitates more precise manufacturing processes, driving significant market growth. According to forecasts, the global CAE market is expected to expand from $7.1 billion in 2025 to approximately $12.9 billion by 2033, reflecting a compound annual growth rate (CAGR) of 7.9%. This growth underscores the increasing importance of AI in optimizing design processes and improving product quality.

Moreover, the market for wireless industrial IoT sensors is projected to surge from an estimated $7.9 billion in 2025 to nearly $21.5 billion by 2033, achieving a staggering CAGR of 13.2%. This expansion illustrates the demand for connected devices that can provide real-time data analysis, further enhancing manufacturing efficiency. As the adoption of AI technologies continues to rise, it is expected that the global AI chip market will surpass $150 billion by 2025, highlighting the critical role that AI hardware will play in advancing industrial automation. These trends indicate a transformative shift in manufacturing, driven by the powerful combination of AI and digital twin technology.

Sustainable Practices: How Green Technology is Shaping Manufacturing Innovations

Sustainability is becoming a cornerstone of innovation in the manufacturing sector, as industries increasingly adopt green technologies to minimize their environmental footprint. Companies are integrating sustainable practices into their operations by leveraging advanced materials, energy-efficient machinery, and waste reduction strategies. This shift only helps in complying with regulations but also enhances corporate reputation and drives consumer loyalty.

Tips for Implementing Sustainable Practices:

- Evaluate Your Supply Chain: Assess the sustainability of your suppliers and opt for those who prioritize green practices, ensuring that your entire production process aligns with eco-friendly standards.

- Invest in Energy-Efficient Equipment: Upgrade to machinery that consumes less energy while boosting productivity. This will not only lower operational costs but also reduce greenhouse gas emissions.

- Implement a Circular Economy Approach: Encourage recycling and reusing materials within your manufacturing processes. This reduces waste and creates a more sustainable model that can benefit both the environment and your bottom line.

By focusing on sustainable innovations, manufacturers can lead the way in creating a cleaner, more efficient future while meeting the demands of environmentally conscious consumers.

Advancements in Robotics: Enhancing Efficiency and Safety in Production Lines

Advancements in robotics are revolutionizing the manufacturing sector, significantly enhancing both efficiency and safety on production lines. As industrial robots become more sophisticated, their capabilities to perform repetitive tasks with precision and speed improve, leading to an increase in overall productivity. Moreover, the integration of smart robotics equipped with artificial intelligence allows for real-time data processing and decision-making, empowering manufacturers to optimize workflows and reduce downtime.

**Tip:** When considering the implementation of robotic systems, it's essential to conduct a thorough assessment of your production line needs. Tailoring robotic solutions to fit specific operational challenges can lead to better investment returns and improved efficiency.

In addition to driving productivity, robotics contributes to a safer work environment. By automating dangerous tasks or handling hazardous materials, robots reduce the risk of workplace injuries, allowing human workers to focus on more complex and creative problem-solving tasks. This shift not only enhances employee safety but also fosters a more innovative workplace culture.

**Tip:** Engage employees in the transition to robotic systems. Training workers to collaborate with robots can improve job satisfaction and increase acceptance of new technologies within the workplace.

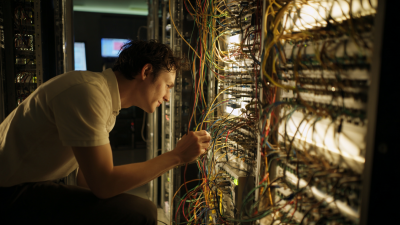

Integration of IoT and Big Data: Revolutionizing Operations and Decision-Making

The integration of IoT (Internet of Things) and Big Data is poised to fundamentally revolutionize operations and decision-making in the manufacturing sector by 2025. According to a report by McKinsey & Company, companies that successfully implement IoT technologies could see a productivity boost of 20-30%, significantly impacting overall operational efficiency. The ability to collect real-time data from interconnected devices enables manufacturers to monitor equipment health, optimize production schedules, and reduce downtime. With predictive analytics, manufacturers can anticipate equipment failures and address potential issues before they escalate, leading to greater reliability and efficiency in production processes.

Moreover, the synergy between IoT and Big Data facilitates informed decision-making by providing businesses with actionable insights derived from vast amounts of collected information. A report from Deloitte highlights that manufacturers leveraging data analytics can improve their profitability by up to 10%. By harnessing these insights, companies are better equipped to streamline their supply chains, tailor production processes, and respond dynamically to market demands. As the manufacturing sector embraces these technological advancements, the capacity for data-driven decision-making will not only enhance operational performance but also promote innovation and competitiveness in an increasingly digital marketplace.

| Trend | Description | Impact on Operations | Data Utilization | Adoption Rate (%) |

|---|---|---|---|---|

| Integration of IoT | Connecting machinery to the internet for real-time data monitoring. | Increased efficiency and reduced downtime. | Real-time analytics for predictive maintenance. | 75% |

| Big Data Analytics | Analyzing vast datasets to improve manufacturing processes. | Enhanced decision-making and operational agility. | Historical trend analysis and demand forecasting. | 68% |

| Automation and Robotics | Implementing robots for repetitive tasks to streamline production. | Higher productivity and improved safety for workers. | Data collected for performance metrics and machine learning. | 65% |

| Augmented Reality (AR) | Using AR for training and maintenance assistance. | Faster training times and reduced error rates. | Visual data overlay enhances learning and troubleshooting. | 50% |

| Sustainability Practices | Integrating sustainable practices to reduce waste and energy consumption. | Lower operational costs and improved brand image. | Data on resource use for continuous improvement. | 72% |

Related Posts

-

Exploring the Impact of Robotic Welding Technology on Manufacturing Efficiency and Quality Metrics

-

Exploring the Future of Precision: How Metal Cutting Laser Machines Revolutionize Manufacturing

-

Unlocking Precision and Efficiency in Manufacturing with Advanced Laser Cutting Machines

-

How to Choose the Right Laser Cutting Service for Your Project Needs

-

Exploring Advanced Metal Welding Techniques: Boosting Efficiency and Quality in Industrial Applications

-

Exploring the Versatility of Metal Tubes: Innovative Applications You Didn't Know About