Top 10 Tips for Sheet Metal Bending Techniques You Need to Know

Sheet metal bending is a fundamental process in manufacturing that allows for the transformation of flat sheets into three-dimensional shapes. Mastering this technique is essential for fabricators who aim to produce high-quality components efficiently. With the right methods and tools, sheet metal bending can be accomplished with precision, ensuring that the final product meets the required specifications. This article presents the top 10 tips for sheet metal bending techniques you need to know, focusing on both the best practices and common pitfalls to avoid.

In the realm of metalworking, having a deep understanding of sheet metal bending techniques can significantly enhance productivity and outcome quality. Whether you're a seasoned professional or just starting in the industry, applying these tips will streamline your bending processes and reduce material wastage. From selecting the appropriate materials to optimizing machine settings, each tip will equip you with the knowledge needed to achieve superior bends while maintaining structural integrity. Join us as we explore essential insights into the art and science of sheet metal bending that every fabricator should incorporate into their workflow.

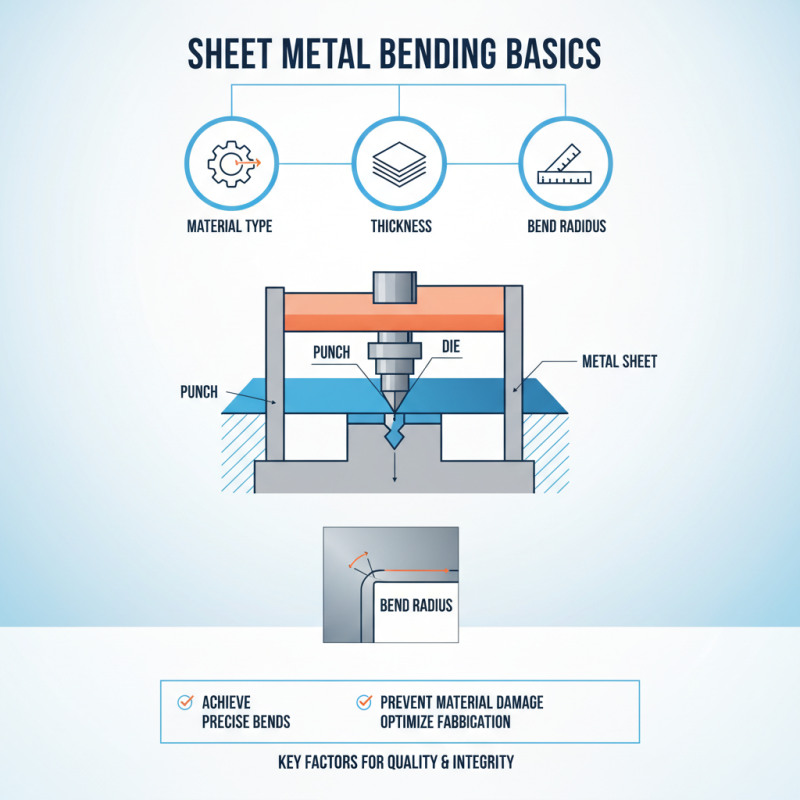

Understanding the Basics of Sheet Metal Bending Techniques

Understanding the basics of sheet metal bending techniques is essential for anyone involved in metal fabrication. Bending is a fundamental process that allows for the shaping of metal sheets into desired forms. Key factors to consider include material type, thickness, and bend radius, as these elements will influence the final outcome. Properly understanding these factors helps in achieving precise bends without compromising the integrity of the material.

One crucial tip for effective sheet metal bending is to always calculate the bend allowance accurately. This measurement determines how much material will be consumed during the bending process, ensuring that the finished piece fits perfectly within the intended design. Another important aspect is to choose the right tooling; the die and punch used in the bending process must match the material specifications and desired bend radius to avoid damaging the sheet.

Moreover, maintaining proper setup of the bending machine is vital. Factors such as the position of the material, machine alignment, and pressure settings play a significant role in achieving quality bends. Regularly checking the machine’s settings can prevent defects and ensure repeatability in production. By mastering these foundational techniques, fabricators can enhance their efficiency and produce high-quality bent metal components.

Essential Tools and Equipment for Effective Bending

When diving into the world of sheet metal bending, having the right tools and equipment is paramount to achieving precise and efficient results. One of the essential tools in this process is the bending brake, which allows for different angles and bends by securing the metal sheet and applying force accurately.

There are various types of bending brakes, from manual to hydraulic, each suited for specific tasks depending on the material thickness and required bend radii.

In addition to a bending brake, a good quality sheet metal shear is vital for preparing your materials. Shears provide clean cuts that minimize the need for additional finishing work.

Accessories like clamping tools ensure that the metal is held securely in place, reducing the risk of error during the bending process. Furthermore, measuring tools, such as calipers and tape measures, are crucial for achieving precise dimensions, enabling the fabricator to plan bends accurately and avoid material wastage.

With the right setup, fabricators can significantly improve their efficiency and output quality.

Common Bending Methods and Their Applications

Bending sheet metal involves several techniques, each suited for specific applications and requirements. One of the most common methods is air bending, which uses a punch to create a specified angle in the sheet. This technique is versatile and allows for adjustments during the bending process, making it ideal for producing components with different angles. Air bending is often used in the fabrication of brackets, supports, and frames where precision is essential but some allowance for adjustments can be beneficial.

Another prevalent method is bottom bending, where the material is pressed against a die. This technique provides high accuracy and repeatability, making it suitable for high-volume production runs. Bottom bending is commonly utilized in scenarios where tight tolerances are crucial, such as in automotive parts or precision enclosures. Both air and bottom bending techniques showcase the importance of selecting the right method based on the desired outcome, from increased flexibility to higher precision, ultimately ensuring that the finished product meets specific engineering requirements.

Tips for Ensuring Precision and Accuracy in Bending

Ensuring precision and accuracy in sheet metal bending is crucial for achieving high-quality results and maintaining the integrity of the materials being worked on. One of the first steps is to thoroughly prepare the sheet metal before bending. This includes selecting the right thickness and type of metal for the project, as well as ensuring all surfaces are clean and free of contaminants that could affect the bending process. Using accurate measurements, preferably with digital tools, can help avoid mistakes that compromise the final product.

Another vital tip is to understand and utilize the appropriate bending tools and machines. Each tool has specific capabilities and limitations, and choosing the right one for the job can greatly enhance precision. It’s also important to calibrate machinery regularly to avoid discrepancies in bending angles and depth. Finally, conducting a test bend on scrap material can provide valuable insights into how the metal behaves under certain conditions, allowing for adjustments to be made before working on the actual piece, thus ensuring greater accuracy in the final outcomes.

Top 10 Tips for Sheet Metal Bending Techniques You Need to Know - Tips for Ensuring Precision and Accuracy in Bending

| Tip No. | Bending Technique | Description | Tools Required | Key Benefits |

|---|---|---|---|---|

| 1 | Air Bending | A common bending method allowing for flexibility in bend angles. | Press brake | Less force required, minimal tooling changes. |

| 2 | Bottom Bending | Bending method that involves the punch touching the die. | Die set, press brake | Increased accuracy, better part consistency. |

| 3 | Coining | A process that deforms the sheet by applying pressure. | Press brake with coining die | High precision, excellent surface finish. |

| 4 | V-Bending | Used for making sharp bends with specific angle requirements. | V-die and punch | Efficient for small production runs. |

| 5 | Rotary Bending | A method involving the rotation of the material through a die. | Rotary bending machine | Ideal for complex shapes. |

| 6 | Stretch Bending | Combines stretching and bending to achieve the desired shape. | Stretch bending machine | Reduces springback, improves finish. |

| 7 | Roll Bending | Bending method that rolls material into circular shapes. | Rolling machine | Creates cylindrical components. |

| 8 | Incremental Bending | Uses a series of small incremental bends to create complex shapes. | Incremental bending machine | Highly versatile and precise. |

| 9 | Die Bending | Utilizes a die to form specific angles and shapes. | Die set, press brake | Consistency and repeatability in production. |

| 10 | Hydraulic Bending | Uses hydraulic pressure for bending operations. | Hydraulic press | Capable of handling thicker materials. |

Safety Measures to Consider While Bending Sheet Metal

When bending sheet metal, safety should always be a primary concern. According to a report by the Occupational Safety and Health Administration (OSHA), improper handling of metal sheets contributes significantly to workplace injuries. In fact, about 25% of injuries in manufacturing are related to materials handling, highlighting the importance of robust safety measures. Before starting any bending operation, it is crucial to wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and steel-toed boots. This way, you can minimize the risk of accidents that could lead to severe injuries.

In addition to wearing PPE, it is essential to maintain a clean and organized workspace. A cluttered environment can cause distractions and increase the likelihood of accidents. Keeping the bending area clear allows for greater mobility and reduces the chance of equipment malfunction. Moreover, implementing proper training programs for operators is vital, as statistics show that well-trained employees are 80% less likely to experience workplace injuries.

Tip: Always check the condition of your bending equipment before use, ensuring that all safety guards are in place and functioning correctly. Another tip is to use proper techniques for handling metal sheets, such as utilizing mechanical aids or partnering with a colleague to lift heavy materials. By following these guidelines, you can significantly enhance safety while optimizing your bending processes.

Top 10 Tips for Sheet Metal Bending Techniques

This bar chart represents the effectiveness of various sheet metal bending techniques based on their popularity and safety considerations. The data reflects the average safety ratings and usage frequency of each technique.

Related Posts

-

2025 Top 10 Water Jet Cutting Machines for Precision and Efficiency

-

2025 Top 5 Industrial Equipment Trends Transforming the Manufacturing Sector

-

What is a Sheet Metal Laser Cutting Machine? Benefits and Applications Explained

-

Exploring the Future of Metal Cutting Technologies: Trends, Innovations, and Market Insights for 2024

-

Exploring Advanced Metal Welding Techniques: Boosting Efficiency and Quality in Industrial Applications

-

2025 Top 5 Water Jet Cutting Innovations You Need to Know